MIL-PRF-123D

4.4 Qualification inspection. Qualification inspection shall be performed at a laboratory acceptable to the

qualifying agency (see 6.3) on sample units produced with equipment and procedures normally used in production.

4.4.1 Sample size. The number of capacitors to be specified for qualification inspection shall be as specified in

table IX and in appendix E of this specification. Each capacitor style shall be qualified separately.

4.4.2 Test routine. Sample units shall be subjected to the qualification inspection specified in table IX in the order

shown. Sample units shall have been subjected to the in-process screening required by this specification and all

sample units shall be subjected to the inspection of group I. The sample shall then be divided as specified in table

IX as applicable.

4.4.3 Failures. Failures in excess of those allowed in table IX shall be cause for refusal to grant qualification

approval.

*

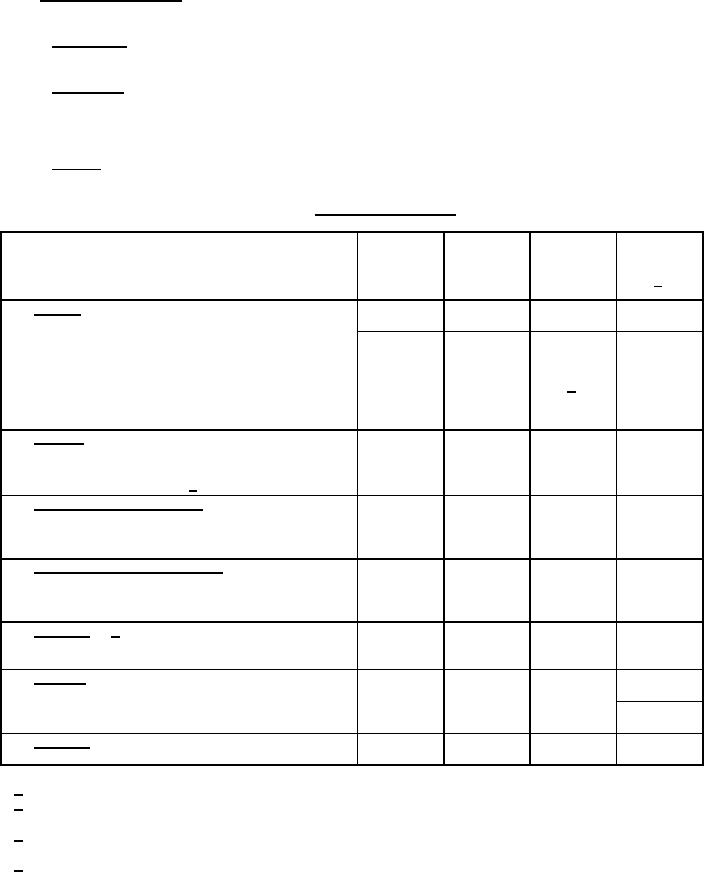

TABLE IX. Qualification inspection.

Number of

Inspection

Requirement Test method Number of

failures

paragraph

paragraph sample units

to be

1/

inspected

Group I

Radiographic inspection (leaded devices only)

All

N/A

Thermal shock and voltage conditioning

Dielectric withstanding voltage

Insulation resistance +25°C

See

186 min

table XVI

2/

Insulation resistance +125°C

Capacitance

Dissipation factor

Group II

Visual and mechanical examination; material, design,

1

construction and workmanship

15

and 3.25

Destructive physical analysis 3/

Group IIIa - Leaded devices

Terminal strength

12

1

Solderability

Resistance to soldering heat

Group IIIb - Nonleaded devices

Terminal strength

12

1

Solderability

Resistance to soldering heat

Group IV

4/

12

1

Voltage-temperature limits

Moisture resistance

Group V

Humidity, steady state, low voltage

0

12

Vibration, high frequency (leaded capacitors only)

1

Resistance to solvents

Group VI

Life

123

1

1/ A sample unit having one or more defects will be charged as a single defective.

2/ Additional samples over the 186 minimum should be included, based on table XVI to allow for the percent

defective allowable. Twelve additional samples shall be required for nonleaded devices.

*

3/ DPA samples shall be divided with 10 samples subjected to group 1 (see 4.6.11.1) and 5 samples to group 2

(see 4.6.11.2).

4/ Leads may be soldered to chip capacitor to facilitate the tests required in group IV.

15

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business