MIL-PRF-123D

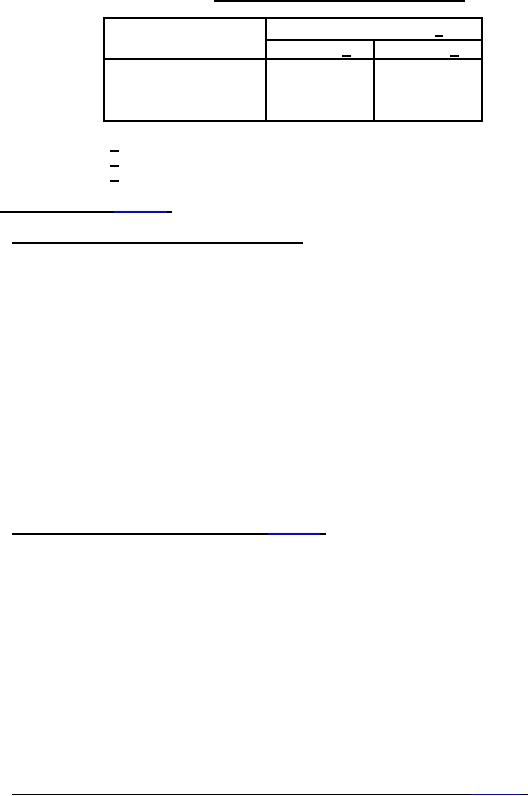

TABLE XVII. Destructive physical analysis sample size.

Minimum sample size 1/

Lot size

Group 1 2/

Group 2 3/

1

-

500

5

3

501

- 10,000

10

4

10,001

- 35,000

25

7

35,001

- 500,000

40

10

1/ No failures allowed

2/ See 4.6.11.1.

3/ See 4.6.11.2.

4.6.12 Terminal strength (see 3.16).

4.6.12.1 Terminal strength (leaded capacitors) (see 3.16). Capacitors shall be tested in accordance with method

211 of MIL-STD-202. The following details and exceptions shall apply:

a. For dual-in-line package (DIP) capacitors, bend leads to full radial (down) position before testing.

b. Test condition A:

(1) Method of holding: Capacitors shall be held by one terminal and the load shall be applied gradually to the

other terminal.

(2) Applied force: 2 ±.1 kilograms.

c. Test condition C: Applicable to radial-lead and DIP units only.

d. Test condition D: Applicable to axial-lead units only.

e. Examination after test: Capacitors shall be visually examined for evidence of loosening or rupturing of the

terminals.

4.6.12.2 Terminal strength (nonleaded capacitors) (see 3.16). Capacitors shall be tested in accordance with

method 211 of MIL-STD-202. The following details and exceptions shall apply:

a. Test condition A:

(1) Capacitors shall have nail head, lead wire (.020 inch to .025 inch) (.51 mm to .64 mm) attached as shown

on figure 5, prior to pull test.

(2) Method of holding: Capacitors shall be held by one terminal and the load shall be applied gradually to the

other terminal.

(3) Applied force: See figure 5.

b. Examination after test: Capacitors shall be visually examined for evidence of loosening or rupturing of the

terminals. Breakage of lead wire or solder interface, which does not expose ceramic, shall not constitute a

failure.

4.6.12.3 Pre-encapsulation terminal strength (dual-in-line package (DIP) capacitors) (see 3.16). Capacitors shall

be tested in accordance with appendix C.

24

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business