MIL-PRF-123D

4.6 Methods of inspection.

4.6.1 Nondestructive internal examination (see 3.5). Capacitors shall be subjected to ultrasonic examination or

some other method of nondestructive internal examination approved by the qualifying activity that allows the

capacitors to meet the requirements of EIA-469. The following details shall also be followed:

a. The ultrasonic test equipment shall be cleaned and maintained in accordance with the test equipment

manufacturer's instructions.

b. The test facility shall establish a setup and operating procedure in accordance with the applicable test

equipment manufacturer's instructions. Testing shall be done in accordance with the test equipment

manufacturer's instructions and the test facility's operating procedures.

c. Each facility shall have a responsible person who has successfully completed a nondestructive testing

course for the ultrasonic test equipment. The ultrasonic test equipment shall not be operated by anyone who

has not been certified and instructed in the use of ultrasonic testing by the designated person. The

responsible person shall prepare a test method that describes the general procedures, requirements, and

techniques for ultrasonic scanning of ceramic chips.

d. Two previously determined bad capacitors of the same dielectric material and size of the parts under test

shall be added to the lot for testing.

e. The test facility shall maintain adequate verification of the results of the ultrasonic examination.

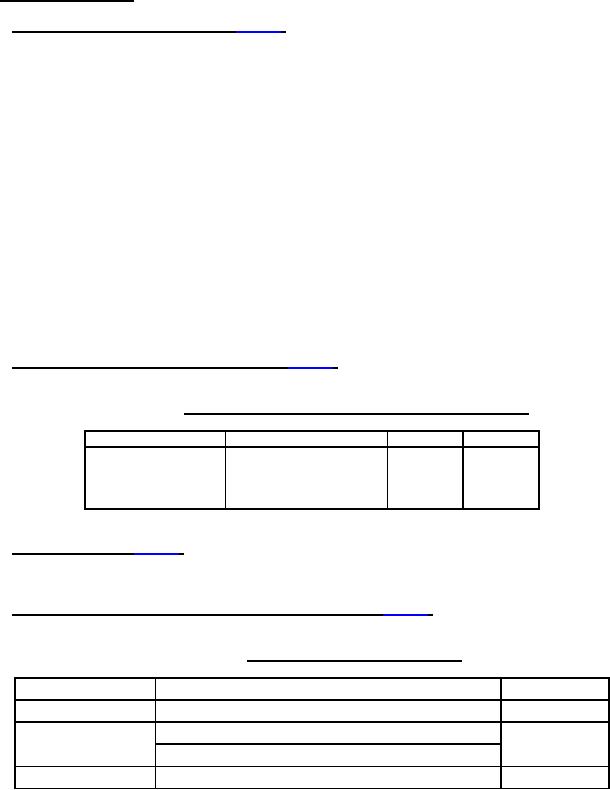

4.6.2 Pre-termination destructive physical analysis (see 3.6). Capacitors shall be examined as specified in EIA-

469 and in accordance with table XIV.

TABLE XIV. Pre-termination destructive physical analysis sample size.

Lot size

Minimum sample size

Accept

Reject

1-

500

14

0

1

501 - 10,000

32

1

2

10,001 - 35,000

50

2

3

35,001 - 500,000

80

3

4

*

4.6.3 Visual examination (see 3.7). Capacitors shall be examined under magnification as specified in the

applicable appendix and shall meet the visual requirements of 3.25 for leaded capacitors and appendix B for

nonleaded capacitors.

4.6.4 Pre-encapsulation terminal strength (leaded capacitors only) (see 3.8). Capacitors shall be examined as

specified in appendix C and in accordance with table XV.

TABLE XV. Pre-encapsulation terminal strength.

Lead configuration

Lead pull minimum

Sample size

Radial per lead

1.8 kg (4.0 lbs)

5 samples

All styles except CKS11 and CKS12 - 1.8 kg (4.0 lbs.)

Axial per lead

5 samples

CKS11 and CKS12 styles - 0.9 kg (2.0 lbs.)

Dual-in-line package

2.14 kg (4.7 lbs.)

5 samples

19

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business