MIL-PRF-123D

*

3.4.5 Pure tin. The use of pure tin, as an underplate or final finish, is prohibited both internally and externally. Tin

content of capacitor components and solder shall not exceed 96 percent, by mass. Tin shall be alloyed with a

minimum of 4 percent lead, by mass (see 6.5).

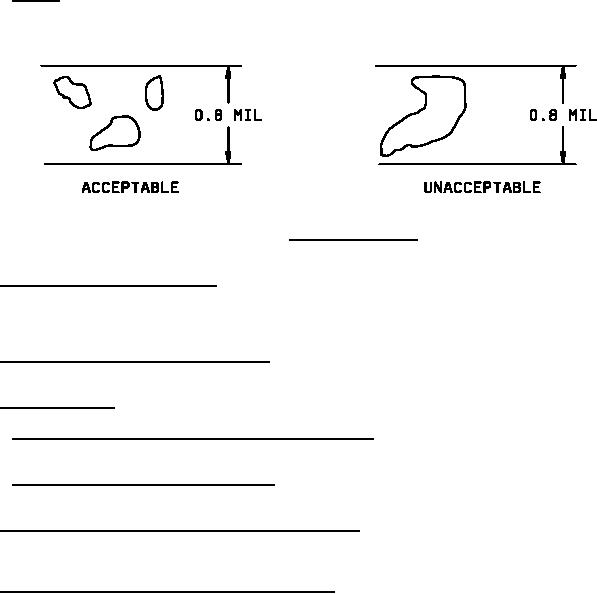

FIGURE 1. Dielectric parameters.

3.5 Nondestructive internal examination. Prior to termination, all capacitors shall be subjected to ultrasonic

examination or some other method of nondestructive internal examination approved by the qualifying activity. The

method of examination shall be determined by the manufacturer. When capacitors are examined as specified in

3.6 Pre-termination destructive physical analysis. When examined as specified in 4.6.2, capacitors shall meet the

requirements of EIA-469.

3.7 Visual examination.

3.7.1 Pre-encapsulation visual inspection (leaded capacitors only). When leaded capacitors are examined as

3.7.2 Visual examination of nonleaded capacitors. When examined as specified in 4.6.3, capacitors shall meet

the visual requirements specified in appendix B.

3.8 Preencapsulation terminal strength (leaded capacitors only). Capacitors shall be tested as specified in 4.6.4

and appendix C. The force shall be applied in the manner specified. In no case shall the termination rupture at a

load less than that specified in table XV.

3.9 Radiographic inspection (encapsulated capacitors only). When radiographed in accordance with 4.6.5,

leaded capacitors shall meet the following requirements (see appendix D):

a. There shall be no evidence of improperly made connections, substandard soldering, structural weakness, or

solder bridging that reduces the distance between terminals to less than 50 percent.

b. The interface between each lead and capacitor element shall have solder for at least 80 percent of the

interface dimension (see figure D-3).

c. The encapsulation material shall have a minimum thickness of .005 inch (0.13 mm) (dimension T, figure D-3),

on all external surfaces of the chip and any protrusions of termination, solder, or lead frame, with the

exception of the lead side of the radial leaded capacitors, which shall have a minimum thickness of .010 inch

d. If a lead has a portion which has been flattened to accommodate the ceramic element more easily, the

formed portion of the lead shall be completely inside the encapsulation material. Any unintentional nick or

deformation of the leads shall not reduce the lead diameter below 90 percent of the minimum diameter

required (see 3.1).

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business