MIL-PRF-55365H

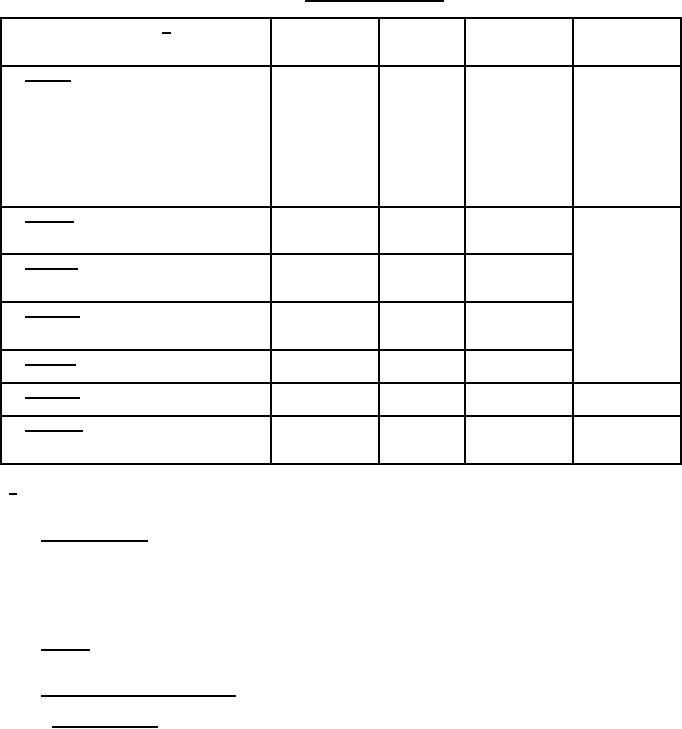

TABLE VI. Qualification inspection.

Inspection 1/

Requirement

Method

Number of

Number of

paragraph

paragraph

sample units

failures allowed

to be inspected

Group I

Voltage aging

DC leakage

Capacitance

178

N/A

Dissipation factor

Equivalent series resistance

(when specified, see 3.1)

Visual and mechanical examination

and 3.30

Group II

Vibration, high frequency

12

Thermal shock (mounted)

Group III

Resistance to soldering heat

18

Moisture resistance

1

Group IV

Stability at low and high temperatures

12

Surge voltage

Group V

Life (at +125�C)

24

Group VI

Life (at +85�C)

102

1

Group VII

Solderability

10

0

Resistance to solvents

1/ For qualification of design changes only, manufacturers may submit Weibull data instead of group V and group

VI test data.

4.4.2 Inspection routine. The sample shall be subjected to the inspections specified in table VI, in the order

shown. All sample units shall be subjected to the inspections of group I. The sample units successfully completing

group I inspection shall then be divided as specified in table VI for group II through group VII inclusive, and subjected

to the inspections for their particular group. For combined voltage group submissions (see A.3.1.2), the smallest and

largest case size, and lowest voltage and highest voltage shall be equally represented in each voltage group

(see 4.6.1.1.1) as closely as possible.

4.4.3 Failures. Failures in excess of those allowed in table VI shall be cause for refusal to grant qualification

approval.

4.4.4 FRL and quality level verification.

4.4.4.1 FRL qualification.

13

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business