MIL-PRF-123D

d. End termination material shall be consistent in formulation and traceable to a single batch and shall be fired

in the same kiln with one temperature profile during the process. All parts shall enter the kiln in one

continuous operation/run for end termination firing.

e. Lot identity shall be maintained from the time the lot is assembled to the time it is accepted.

f. The lot date code shall be assigned prior to lead attachment for leaded devices and prior to final end

termination for nonleaded devices.

4.5.2.2 Group A inspection. Group A inspection shall consist of the tests and examinations specified in table XI.

The following details shall apply:

a. Failure to meet destructive physical analysis (DPA) limits shall cause the lot to be rejected.

b. A summary of the results of group A inspection on each lot that meets requirements shall be submitted to the

purchaser with the parts.

c. A copy of the applicable DPA report shall be submitted to the purchaser with each lot of parts.

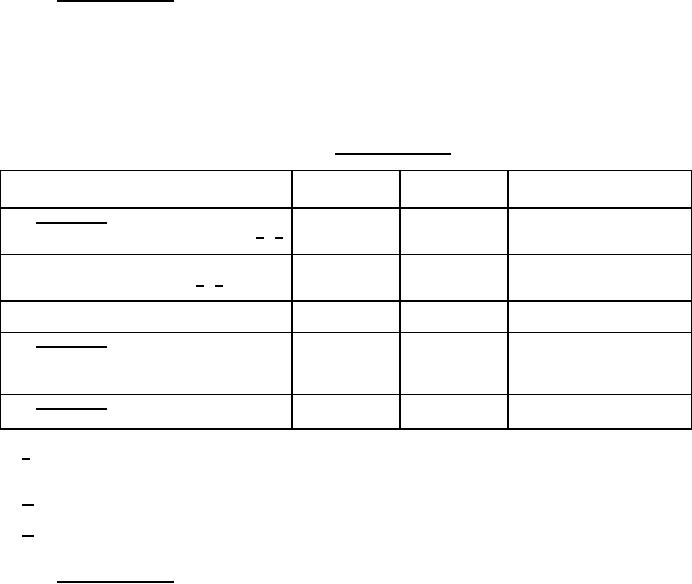

TABLE XI. Group A inspection.

Inspection

Requirement

Test method

Sampling procedure

paragraph

paragraph

Subgroup 1

Thermal shock and voltage conditioning 1/ 2/

100% inspection

100% inspection

Voltage conditioning at +85°C 2/ 3/

(see table XVI, PDA overall

requirement only)

Radiographic inspection (encapsulated

100 % inspection

capacitors only)

Subgroup 2

Visual and mechanical inspection; material,

20 samples

physical dimensions, design, construction,

0 failures

and 3.25

marking, and workmanship

Subgroup 3

Destructive physical analysis

1/ For solder coated nonleaded capacitor chips, thermal shock and voltage conditioning in accordance with

4.6.6.1 and 4.6.6.2 may be performed prior to addition of final metallization; and if performed, shall not be

required during group A.

2/ The DWV post test is not applicable if optional voltage conditioning was performed at 250 percent or more of

the rated voltage.

3/ Voltage conditioning at +85°C is only required for solder coated nonleaded capacitor chips that had voltage

conditioning performed prior to final metallization.

4.5.2.3 Group B inspection. Group B inspection shall consist of the tests specified in table XII and shall be

performed on sample units from lots that have been subjected to and have passed group A inspection. Copies of

group B data shall be forwarded to purchaser with parts. Parts may not be shipped until the conclusion of 1,000

hours of life test.

17

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business