MIL-PRF-55365H

4.6.1.2.3.2 Weibull. Subgroup 1 tests shall be performed on an inspection lot basis (see 4.6.1.1.2) on 100 percent

of the product supplied under this specification. Requirements for the infant mortality period and Weibull FRL grading

shall be in accordance with 4.7.20.

4.6.1.2.3.3 Subgroup 1a tests (for "T" level only). Subgroup 1a test (for "T" level only) Radiographic inspection is

performed on 100% of the T level product supplied under this specification. Capacitors failing this inspection shall be

removed from the lot. Destructive physical analysis shall be performed on an inspection lot. If a lot is rejected on the

DPA sample, the manufacturer has the option to convert the lot to standard product (Product level designators A, B,

C, D, M, P, R, or S) if the DPA defect is not considered a reliability risk.

*

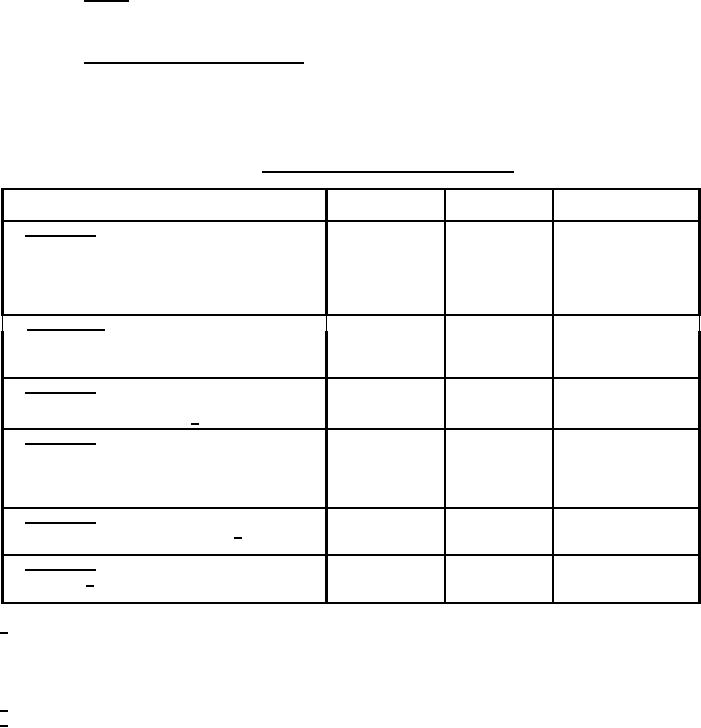

TABLE VIII. Group A inspection for Weibull distribution.

Inspection

Requirement

Test method

Sampling procedure

paragraph

paragraph

Subgroup 1

Reflow conditioning

Thermal shock (unmounted)

100% inspection

Surge current option C (when specified in PIN)

Weibull FRL grading

Surge current options A or B (when specified in PIN)

Subgroup 1a

100%

Radiographic inspection (T level only)

5 samples

Destructive physical analysis (T level only)

0 failures

Subgroup 2

Mechanical examination

(physical dimensions only) 1/

See table IX

Subgroup 3

Visual examination

(T level 100%)

Materials

13 samples

Marking

0 failures

Workmanship

Subgroup 4

Stability at low and high temperatures 2/

13 samples

0 failures

Subgroup 5

Solderability 3/

13 samples

0 failures

1/ This can be eliminated if the manufacturer has demonstrated process control under the SPC program (see 3.3.1),

and has been approved by the qualifying activity. If the design, material, construction, or processing of the part is

changed or, there are any quality problems, or failures, the qualifying activity may require resumption of the

specified testing. Deletion of testing does not relieve the manufacturer from meeting the test requirement in case

of dispute.

2/ Sampling need only conform to the requirements of 4.6.1.1.1 (exponential distribution) inspection lot.

3/ Not applicable to gold plated termination finishes.

18

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business