MIL-PRF-55365H

4.6.1.2.3.3 Manufacturer's production inspection. If the manufacturer performs tests similar to those specified in

group A, subgroup 1, as the final step of the manufacturing process, the subgroup 1 test may be eliminated when

approved by the qualifying activity. The following criteria shall be complied with:

a. The manufacturer production tests are identical or more stringent than those specified for subgroup 1 tests.

b. One hundred percent of the product shall be subjected to these tests.

c. Failure criteria are identical, the same as, or more stringent than, the subgroup 1 tests.

d. Lot rejection criteria are identical to, or more stringent than, the subgroup 1 tests.

e. Once approved, future changes require approval from the qualifying activity.

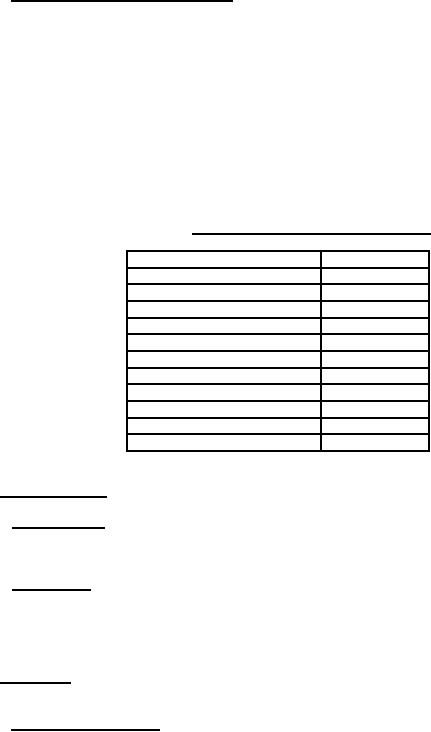

TABLE IX. Sampling plans for group A, subgroup 2.

Lot size

Sample size

1-

13

100%

14 -

150

13

151 -

280

20

281 -

500

29

501 -

1,200

34

1,201 -

3,200

42

3,201 -

10,000

50

10,001 -

35,000

60

35,001 - 150,000

74

150,001 - 500,000

90

500,001 -

UP

102

4.6.1.2.4 Subgroup 2 tests .

4.6.1.2.4.1 Sampling plans. Subgroup 2 tests shall be performed on an inspection lot basis. Samples subjected

to subgroup 2 shall be selected in accordance with table IX based on the size of the inspection lot. In the event of

one or more failures, the lot shall be rejected.

4.6.1.2.4.2 Rejected lots. The rejected lot shall be segregated from new lots and those lots that have passed

inspection. The rejected lot shall be 100 percent inspected for those quality characteristics found defective in the

sample. Any defectives found shall be removed from the lot. A new sample of parts shall then be randomly selected

in accordance with table IX. If one or more defects are found in this second sample the lot shall be rejected and shall

not be supplied to the specification.

4.6.1.2.5 Subgroup 3. Subgroup 3 shall be performed on an inspection lot basis on 13 sample units with no

failures allowed with the exception that "T" level lots are inspected 100 percent.

4.6.1.2.5.1 Rejected non T level lots. The entire rejected inspection lot shall be segregated from new inspection

lots and those inspection lots that have passed inspection. The rejected inspection lot shall be 100 percent inspected

for those quality characteristics found defective in the sample. Any defectives found shall be removed from the lot. A

new sample of 13 parts shall then be randomly selected. If one or more defects are found in this second sample, the

lot shall be rejected and shall not be supplied to the specification.

19

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business