MIL-PRF-23269G

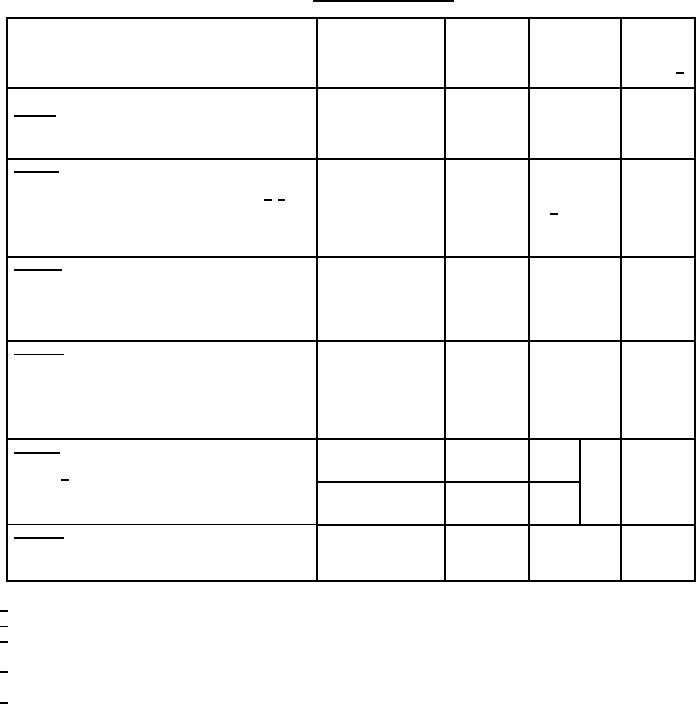

TABLE III. Qualification inspection.

Number of

Number of

Test

Examination or test

Requirement

failures

sample units

method

paragraph

allowed 1/

to be

paragraph

inspected

Group I

115

Seal

High voltage stabilization

Group II

Visual and mechanical examination (external) 2/ 3/

4/ 115

and 3.27

1

Insulation resistance (at 125°C and 25°C)

Capacitance

Dissipation factor

Group III

Thermal shock

1

12

Quality factor (Q)

Shock, specified pulse

Vibration, high frequency

Group IV

Solderability

1

12

Terminal strength

Barometric pressure

Temperature coefficient and capacitance drift

Salt atmosphere

Group V

1

10

5

Fungus 5/

Resistance to solvents

5

Resistance to soldering heat

Moisture resistance

Group VI

1

50

Life (rated condition)

30

Life (accelerated condition)

1/

A specimen having one or more defects shall be considered as a single failure.

2/

Nondestructive tests.

3/

Marking defects are based on visual examination only and shall be charged only for illegible, incomplete, or

incorrect marking.

4/

One additional sample unit is included in each sample of 115 sample units to permit substitution for the failure

allowed in group II.

5/

Certification of fungus resistance may be substituted for testing.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business