MIL-PRF-23269G

*

4.6.2 Periodic group C inspection. Group C inspection shall be performed on sample units which have been

subjected to and have passed the applicable tests for group A inspection and shall consist of the tests specified in

table V, in the order shown. Delivery of products which have passed group A inspection shall not be delayed

pending the results of periodic inspection.

4.6.2.1.1 Sampling plan.

*

4.6.2.1.1.1 Group I. Fifty-one sample units shall be taken from production every 2 months and subjected to the

applicable tests for their particular subgroup. Allowable failures shall be as specified in table V.

4.6.2.1.1.2 Group II. A minimum of 10 sample units shall be selected from each inspection lot produced during a

2-month period. Allowable failures shall be as specified in MIL-STD-690. The accumulated data shall be used for

maintenance and extension of FR qualification.

4.6.2.1.2 Noncompliance. If a sample unit fails to pass group C inspection, the manufacturer shall notify the

qualifying activity of such failure and take corrective action on the materials or processes, or both, as warranted, and

on all units of product which can be corrected and which were manufactured under essentially the same conditions,

with essentially the same materials and processes, and which are considered subject to the same failure.

Acceptance of the product shall be discontinued until corrective action acceptable to the Government, has been

taken. After the corrective action has been taken, group C inspection shall be repeated on additional sample units

(all inspection or the inspection which the original sample failed, at the option of the Government). Group A

inspection may be reinstituted; however, final acceptance shall be withheld until the group C inspection has shown

that the corrective action was successful. In the event of failure after re-inspection, information concerning the

failure and corrective action taken shall be furnished to the cognizant inspection activity and the qualifying activity.

*

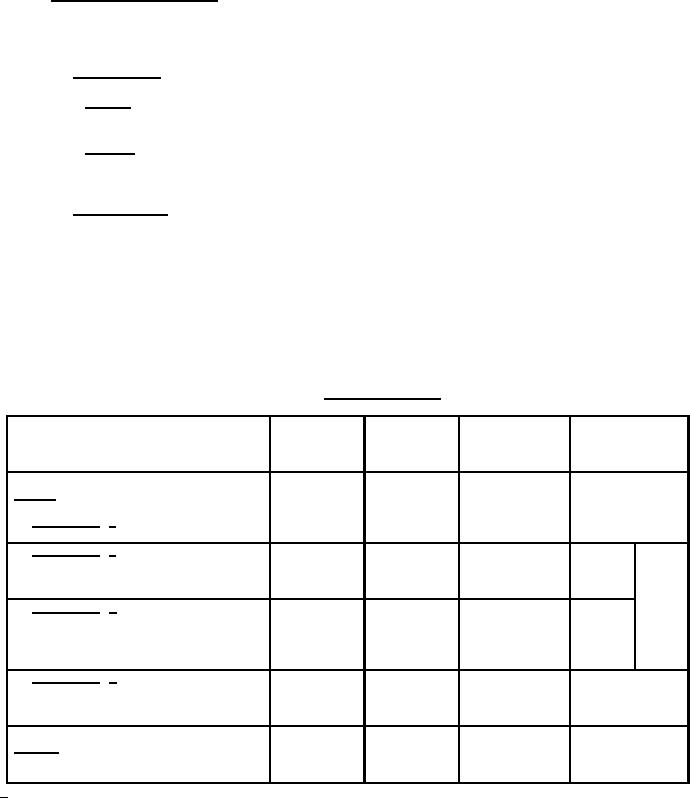

TABLE V. Group C inspection.

Number of

Number of

Test method

Test

Requirement

failures allowed

sample units

paragraph

paragraph

to be inspected

Group I

Subgroup IA 1/

1

24

Thermal shock

Subgroup IB 1/

Quality factor(Q)

1

12

Shock, specified pulse

Vibration, high frequency

1

Subgroup IC 1/

Terminal strength

1

12

Barometric pressure

Temperature coefficient and capacitance drift

Salt atmosphere

Subgroup ID 1/

Resistance to solvents

0

3

Resistance to soldering heat

Moisture resistance

Group II

(See 4.6.2.1.1.2)

10 minimum

Life (accelerated conditions)

*

1/ If the manufacturer can demonstrate that these tests have been performed five consecutive times with zero

failures, then these tests, with the approval of the qualifying activity, can be deleted. The manufacturer, however,

shall perform these tests every three years after the deletion as part of long term design verification. If the

design, material, construction, or processing of the part is changed or, if there are any quality problems, the

qualifying activity may require resumption of the specified testing. Deletion of testing does not relieve the

manufacturer from meeting the test requirement in case of dispute.

13

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business