MIL-PRF-23269G

3. REQUIREMENTS

3.1 Specification sheets. The individual item requirements shall be as specified herein and in accordance with

the applicable specification sheet. In the event of any conflict between the requirements of this specification and the

specification sheet, the latter shall govern.

3.2 Qualification. Capacitors furnished under this specification shall be products that are authorized by the

qualifying activity for listing on the applicable Qualified Products List (QPL) at the time of award of contract (see 4.4

and 6.3). Authorized distributors which are approved to MIL-STD-790 distributor requirements by the QPL

manufacturers are listed in the QPL.

3.3 QPL system. The manufacturer shall establish and maintain a QPL system for parts covered by this

specification. Requirements for this system are specified in MIL-STD-690 and MIL-STD-790. In addition the

manufacturer shall also establish a SPC and PPM system that meets the requirements as detailed in 3.3.1 and 3.3.2

respectively. Reliability of capacitors furnished under this specification shall be established and maintained in

accordance with the procedures and requirements specified in MIL-STD-690 and MIL-STD-790 with details specified

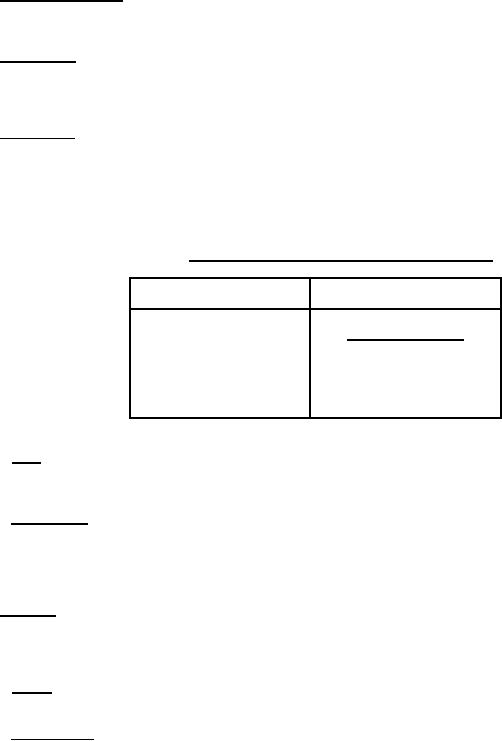

TABLE I. FRL (established at a 90 percent confidence level).

Symbol

FRL

Percent/1,000 hour

M

1.0

P

0.1

R

0.01

S

0.001

3.3.1 SPC. As part of the overall MIL-STD-790 QPL system, the manufacturer shall establish a SPC system that

meets the requirements of EIA-557. The manufacturer shall demonstrate control of the temperature coefficient of

capacitance and lead integrity in the process.

3.3.2 PPM system. As part of the overall MIL-STD-790 QPL system, the manufacturer shall establish a PPM

system of assessing the average outgoing quality of lots in accordance with EIA-554-1. Data exclusion, in

accordance with EIA-554-1, may be used with approval of the qualifying activity. The ppm system shall identify the

ppm rate at the end of each month and shall be based on six month moving average. Style reporting may include

ER style combinations.

3.4 Materials. The material shall be as specified herein. However, when a definite material is not specified, a

material shall be used which will enable the capacitors to meet the performance requirements of this specification.

Acceptance or approval of any constituent material shall not be construed as a guaranty of the acceptance of the

finished product.

3.4.1 Solder. Solder for electrical connections shall be selected to meet the requirements of this specification. In

no case shall the solder start to melt at a temperature of less than 200°C.

3.4.2 Soldering flux. The use of materials that leave potentially corrosive residues should be avoided. Where

such materials must be used to ensure the satisfactory performance of a process, all potentially corrosive residues

must be neutralized and removed to prevent deterioration of the capacitor from the occurrence of related corrosion in

application.

3

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business