MIL-PRF-49464C

4.4.3 Failures. Failures in excess of those allowed in table V shall be cause for refusal to grant qualification

approval.

4.4.4 FRL and quality level verification.

4.4.4.1 FR qualification and lot conformance FR inspection. FR qualification and lot conformance FR inspection

shall be in accordance with the general and detailed requirements of MIL-STD-690 and the following details:

a. Procedure I: Qualification at the initial FR level. Level M (1.0 percent) of FRSP-90 shall apply. Sample

units shall be subjected to the qualification inspection specified in group I, table V prior to being tested as

specified in group IV, table V (see 4.4.2).

b. Procedure II: Extension of qualification to lower FR levels. To extend qualification to the P (0.1 percent), R

(0.01 percent), and S (0.001 percent) FR levels, two or more voltages within a temperature coefficient limit

may be combined. For FR levels R and S, two or more voltage temperature characteristics may be

combined.

c. Procedure III: Maintenance of FR level qualification. Maintenance period B of FRSP-10 shall apply.

Regardless of the number of production lots produced during this period, the specified number of unit hours

shall be accumulated to maintain qualification.

4.4.4.2 Quality level verification. The contractor is responsible for establishing a quality system to verify the ppm

defect level of lots. The ppm defect level shall be based on a 6-month moving average.

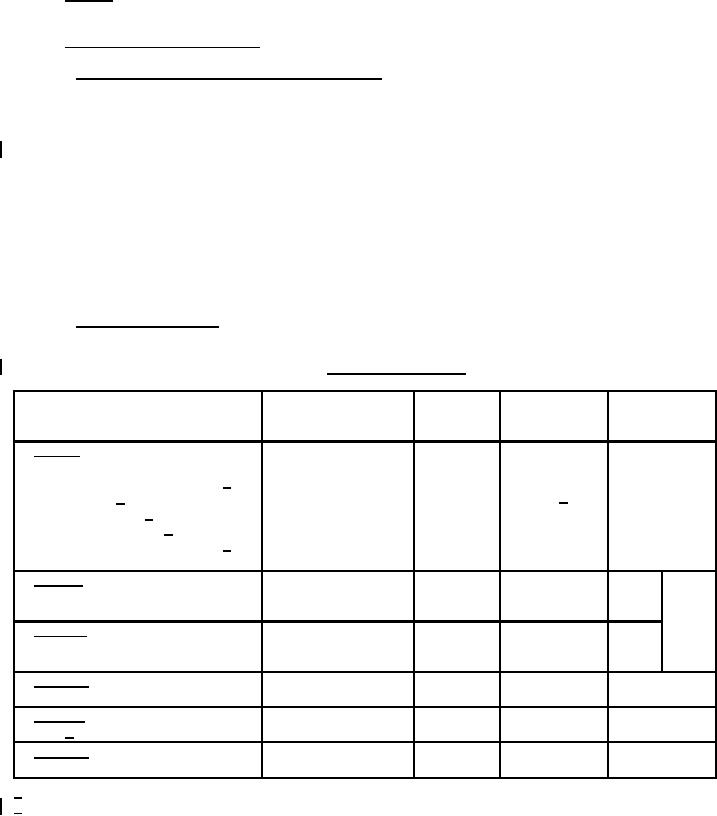

TABLE V. Qualification inspection.

Number of

Number of

Test method

defectives

Inspection

Requirement paragraph

sample units to

paragraph

permitted

be inspected

Group I

Thermal shock and voltage conditioning

Insulation resistance (+125°C) 1/

67 2/

0

Capacitance 1/

Dissipation factor 1/

Insulation resistance 1/

Dielectric withstanding voltage 1/

Visual and mechanical inspection

Group II

Bond strength

6

1

Die shear strength

1

Group III

Temperature coefficient limits

18

1

Immersion

Group IV

Life

25

1

Group V

Fungus 2/

6

0

Group VI

Humidity, steady state, low voltage

12

0

1/ Performed as part of voltage conditioning.

2/ Certification of fungus resistance may be substituted for testing. If certification is given for fungus (see 3.17), only

61 samples are needed.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business