MIL-DTL-3965H

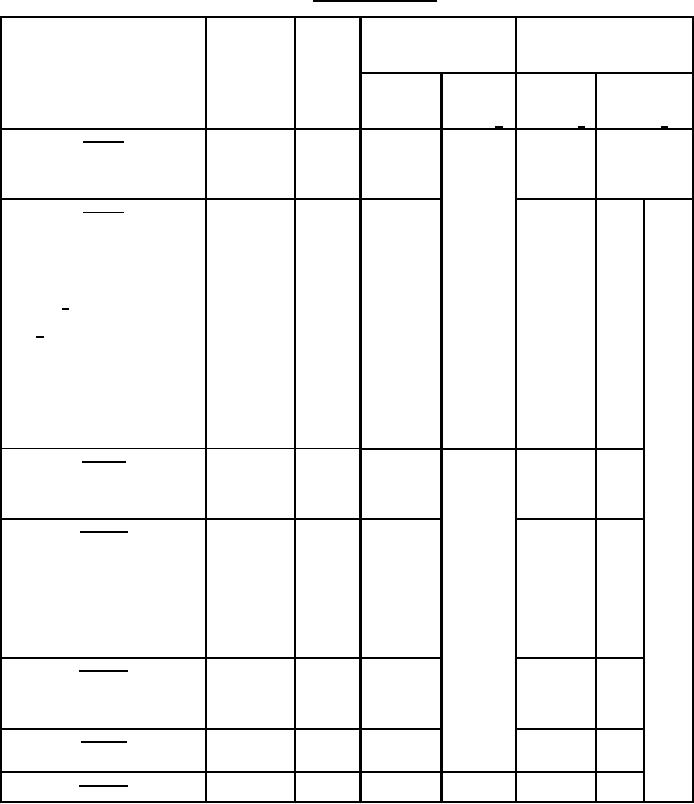

TABLE V. Qualification inspection.

Method

Examination or test

Requirement

Other styles

Styles CL14, CL16,

paragraph

paragraph

CL17, CL18, andCL55

Number of

Number

Number

Number of

sample

of

of

sample

units to be

failures

failures

units to be

inspected 2/

allowed 1/

allowed 1/

inspected

Group I

Visual and mechanical examination

4.7.1

---

(internal) materials, design,

2

2

3.1, 3.3, 3.5,

0

construction, and workmanship

3.25, and 3.26

Group I

Visual and mechanical examination

4.7.1

---

(internal) materials, design,

3.1, 3.3, 3.4,

construction, and workmanship

3.25, and 3.26

Visual and mechanical examination

---

(external):

4.7.1

3.1, 3.3, 3.25,

Physical dimensions, materials,

marking 3/, and workmanship

and 3.26

0

26

37

1

Seal 1/

3.6

4.7.2

Dielectric withstanding voltage

(style CL55)

3.7.1

4.7.3.1

Insulation resistance (style

CL55)

3.8

4.7.4.1

DC leakage

Capacitance

3.9

2

4.7.5

3.10

Dissipation factor

4.7.6

3.11

4.7.7

Group II

Shock (specified pulse)

3.12

4.7.8

Vibration, high frequency

3.13

4.7.9

1

6

4

Thermal shock

3.14

4.7.10

Salt atmosphere

3.15

4.7.11

Group III

Solderability (when applicable)

3.16

4.7.12

Terminal strength

3.17

4.7.13

Surge voltage

3.18

4.7.14

Moisture resistance

3.19

4.7.15

4

6

1

Dielectric withstanding voltage

(insulated styles only)

3.7.2

4.7.3.2

Insulation resistance insulated

1

styles only)

3.8

4.7.4.2

Low temperature (storage)

3.20

4.7.16

Group IV

Stability at low and high

temperatures

3.21

4.7.17

4

6

1

AC ripple life at 85°C (when

3.27

4.7.21

specified, see 3.1)

Group V

Life at 85°C (2,000 hours)

8

4.7.18.1

3.22.1

12

1

4.7.19

3.23

Barometric pressure (reduced)

Group VI

Life at 125°C

3.24

4.7.20

6

0

6

1

See footnotes at top of next page.

13

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business