MIL-DTL-3965H

4.6 Conformance inspection.

4.6.1 Inspection of product for delivery. Inspection of product for delivery shall consist of groups A and B

inspection (see 4.6.2.1.4).

4.6.1.1 Inspection lot. An inspection lot shall consist of one or more styles of capacitors of either tubular foil, foil

package, tubular slug, or slug package construction (see 3.1), produced on the same production line or lines, under

essentially the same conditions and offered for inspection during a single work week. The sample selected from a lot

shall be representative of the styles and voltages in the lot. Hermetically sealed units shall be kept separate from

nonhermetically sealed units. The following style groupings may be used for quality conformance inspection:

Group 1 - CL10, CL13, CL14, CL16, CL17, CL18, and CL55.

Group 2 - CL66 and CL67

4.6.1.2 Group A inspection. Group A inspection shall consist of the examination and tests specified in table VII, in

the order shown.

4.6.1.2.1 Sampling plan. The sampling plan for subgroups 1 and 2 shall be as specified in table VII.

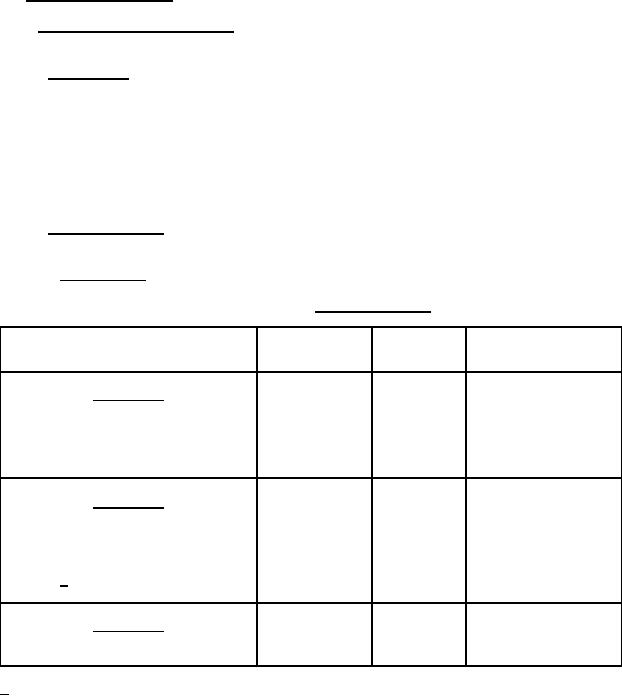

TABLE VII. Group A inspection.

Requirement

Method

Sampling

Examination or test

paragraph

paragraph

procedure

Subgroup 1

DC leakage

3.9

4.7.5

Capacitance

3.10

4.7.6

20 samples

Dissipation factor

3.11

0 failures

4.7.7

Subgroup 2

Visual and mechanical examination

(external):

---

4.7.1

13 samples

Materials

3.1 and 3.3

0 failures

Physical dimensions

3.1

Marking 1/

3.25

Workmanship

3.26

Subgroup 3

5 samples

Solderability (when applicable, see 3.1)

3.16

4.7.12

0 failures

1/ Marking defects shall be based on visual examination only. Any subsequent electrical defects shall not

be used as a basis for determining marking defects.

15

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business