MIL-DTL-3965H

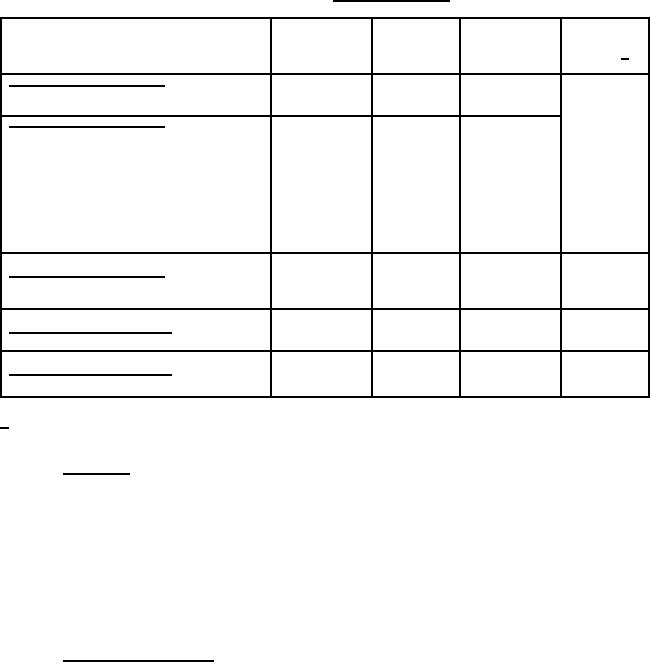

TABLE IX. Group C inspection.

Number of

Number of

Test

Requirement

failures

sample units

paragraph

paragraph

Test

allowed 1/

to be

inspected

Subgroup 1 (every 6 months)

Shock (specified pulse)

12

4.7.8

3.12

Vibration, high frequency

4.7.9 1

3.13

Subgroup 2 (every 6 months)

3.17

Terminal strength

4.7.13

3.18

Surge voltage

4.7.14

3.19

Moisture resistance

4.7.15

Dielectric withstanding voltage

1

12

3.7.2

(insulated styles only, see 3.1)

4.7.3

Insulation resistance

3.8

(insulated styles only, see 3.1)

4.7.4.2

Seal (hermetically-sealed styles,

(see 3.1)

3.6

4.7.2

Subgroup 3 (every 6 months)

Low temperature (storage)

(all styles)

12

4.7.16

3.20

1

Subgroup 4 (every 12 months)

Life at 85°C (1,760 hours)

4.7.18.3

3.22.3

1

10

Subgroup 5 (every 12 months)

3.24

4.7.20

Life at 125°C (see 3.1)

1

6

1/ A sample unit having one or more defects shall be considered as a single failure.

4.7.3.1 Style CL55. The following details and exception shall apply:

a.

Special preparation: The two terminals shall be electrically connected together before application of voltage.

Magnitude of test voltage: 300 volts ±10 percent.

b.

c.

Nature of potential: DC.

d.

Points of application of test voltage: Between terminals and case.

e.

Examination after test: Capacitors shall be examined for evidence of damage and breakdown.

4.7.3.2 Insulated styles (see 3.1). The following details and exception shall apply:

a.

Magnitude and nature of test voltage: 2,000 V dc, minimum.

b.

Points of application of test voltage: Between the capacitor case and a V-block in intimate contact with the

sleeving.

c

Examination after test: Insulating sleeving shall be examined for evidence of breakdown.

19

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business