MIL-PRF-49137E

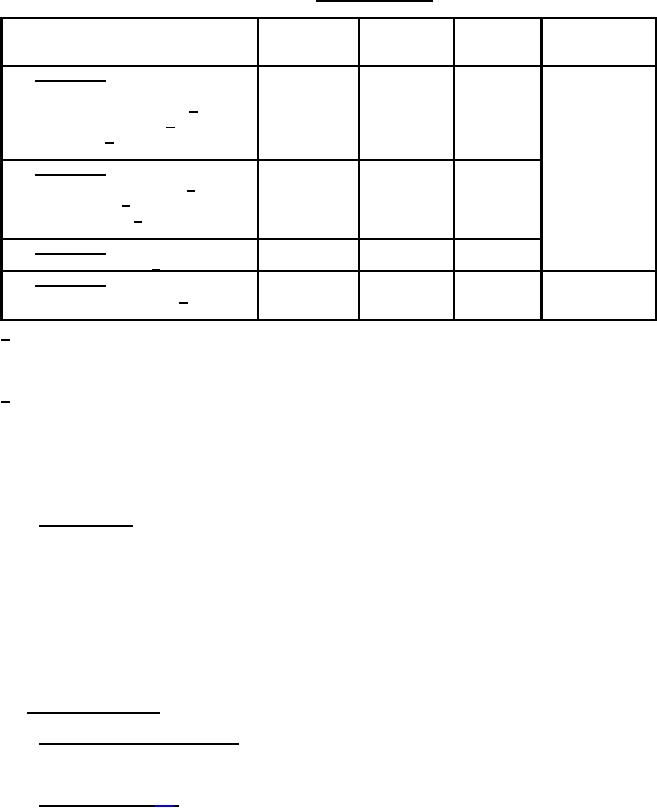

TABLE VII. Group C inspection.

Test

Units

No. of

Requirement

method

to be

defectives

Inspection

paragraph

paragraph

inspected

allowed

Subgroup 1

Shock (specified pulse)

(polarized capacitors only) 1/

12

Vibration, high frequency 1/

Thermal shock 1/

Subgroup 2

Resistance to soldering heat 2/

Terminal strength 2/

18

1

Moisture resistance 2/

Subgroup 3

10

Resistance to solvents 1/

Subgroup 4

Life (1,000 hours at +85°C) 1/

25

1

1/ If the manufacturer can demonstrate that this test has been performed five consecutive times with zero failures,

the frequency of this test, with the approval of the qualifying activity, can be performed on an annual basis. If

the design, material, construction, or processing of the part is changed, or if there are any quality problems or

failures, the qualifying activity may require resumption of the original test frequency.

2/ If the manufacturer can demonstrate that this test has been performed five consecutive times with zero failures,

this test, with the approval of the qualifying activity, can be deleted. The manufacturer, however, shall perform

this test every three years after the deletion as part of long term design verification. If the design, material,

construction or processing of the part is changed or, if there are any quality problems, the qualifying activity may

require resumption of the specified testing. Deletion of testing does not relieve the manufacturer from meeting

the test requirement in case of dispute.

4.7.2 Noncompliance. If a sample fails to pass group C inspection the manufacturer shall immediately notify the

qualifying activity and the cognizant inspection activity of such failure and take corrective action on the materials or

processes, or both, as warranted, and on all units of product which can be corrected and which were manufactured

under essentially the same conditions, with essentially the same materials, processes, etc., and which are considered

subject to the same failure. Acceptance and shipment of the product shall be discontinued until corrective action,

acceptable to the qualifying activity, has been taken. After the corrective action has been taken, group C inspection

shall be repeated on additional sample units (all inspections or the inspection which the original sample failed, at the

option of the qualifying activity). Group A and group B inspection may be reinstituted, however, final acceptance and

shipment shall be withheld until the group C inspection has shown that the corrective action was successful. In the

event of failure after reinspection, information concerning the failure shall be furnished to the cognizant inspection

activity and the qualifying activity.

4.8 Methods of inspection.

4.8.1 Visual and mechanical inspection. Capacitors shall be inspected to verify that the materials, design,

construction, physical dimensions, marking and workmanship are in accordance with the applicable requirements

4.8.2 Voltage aging (see 3.5). Capacitors shall be subjected to a minimum of 125 percent of dc rated voltage for 2

hours minimum, at a temperature of +85°C ±5°C. The voltage aging circuit shall have a series resistance of 3.0

ohms maximum. Power source shall not be less than 5 amperes. Capacitors shall then be stabilized at room

temperature and examined for evidence of mechanical damage.

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business