MIL-PRF-49137E

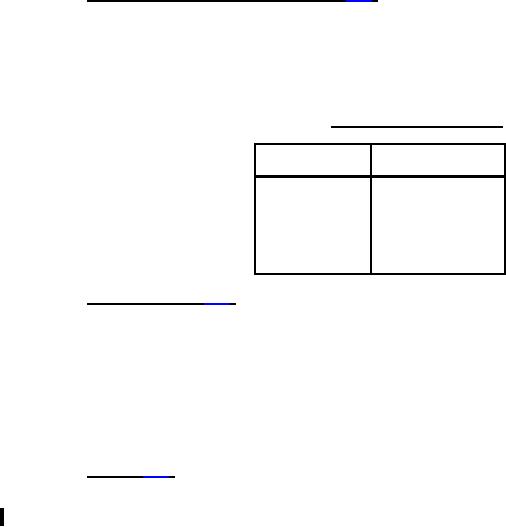

4.8.13 Stability at low and high temperatures (see 3.16). DC leakage, capacitance, and dissipation factor shall be

measured as specified in 4.8.4, 4.8.5, and 4.8.6, respectively, at each of the temperatures specified in table VIII

except that dc leakage measurements at -55°C (step 2) are not required. The capacitors shall be brought to thermal

stability at each test temperature. Thermal stability will have been reached when no further change in capacitance is

observed between two successive measurements taken at intervals of 15 minutes +2 minutes, -0 minute. Capacitors

may be dried at +85°C for 30 minutes +4 minutes, -0 minute prior to start of tests, however, the decision to reject the

parts shall be made on those parts that have been dried.

TABLE VIII. Temperature for stability test.

Test temperature

Step

(°C)

+25 ±2

1

2

-55 +0, -3

+25 ±2

3

4

+85 +4, -0

+25 ±2

5

4.8.14 Surge voltage (see 3.17). Capacitors shall be subjected to 1,000 cycles of the applicable surge voltage

specified in table I. The ambient temperature during cycling (see 3.1), shall be +85°C ±5°C. Each cycle shall consist

of a 30 second +2 second, -0 second surge voltage application followed by a 30 second +2 second, -0 second

discharge period. Voltage application shall be made through a resistor of 33 ohms. The tolerance of the resistor

shall be ±5 percent. Each surge voltage cycle shall be performed in such a manner that the capacitor is shorted

terminal to terminal through a copper bar, or an equivalent low resistance at the end of the 30 second +2 second, -0

second application. An alternate method of shorting the capacitors is discharged through the same resistance that is

utilized for charging. After the final cycle, the capacitors shall be stabilized at the inspection conditions specified in

4.3, and the dc leakage, capacitance, and dissipation factor shall be measured as specified in 4.8.4, 4.8.5, and 4.8.6,

respectively.

4.8.15 Life (see 3.18). Capacitors shall be tested in accordance with method 108 of MIL-STD-202. The following

details and exceptions shall apply:

a. Test temperature and tolerance: +85°C +4°C, -0°C.

b. Operating conditions: DC rated voltage (see 3.1), shall be applied gradually (not to exceed 5 minutes either

by a slow buildup of the voltage or through a resistor which shall be shorted out within 5 minutes). Voltage

shall be applied continuously, except for measurement periods. The impedance of the voltage source, as

seen from the terminals of each capacitor, shall not exceed 3 ohms. Storage batteries or an electronic power

supply capable of supplying at least 1 ampere when a capacitor is shorted shall be used.

c. Test condition letter D (1,000 hours).

d. Measurements during exposure: DC leakage shall be measured as specified in 4.8.4 at 0 hour; 240 hours

+48 hours -0 hour; 1,000 hours +48 hours, -0 hour. The manufacturer may option to measure dc leakage at

+85°C; however, if the capacitors fail to meet the dc leakage requirement in 3.18 the measurement shall be

made at +25°C.

e. Measurements after exposure: Capacitors shall be returned to the inspection conditions specified in 4.3 and

visually examined for evidence of harmful corrosion, mechanical damage, or obliteration of marking (if

applicable); dc leakage, capacitance and dissipation factor shall then be measured as specified in 4.8.4,

15

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business