MIL-PRF-39001E

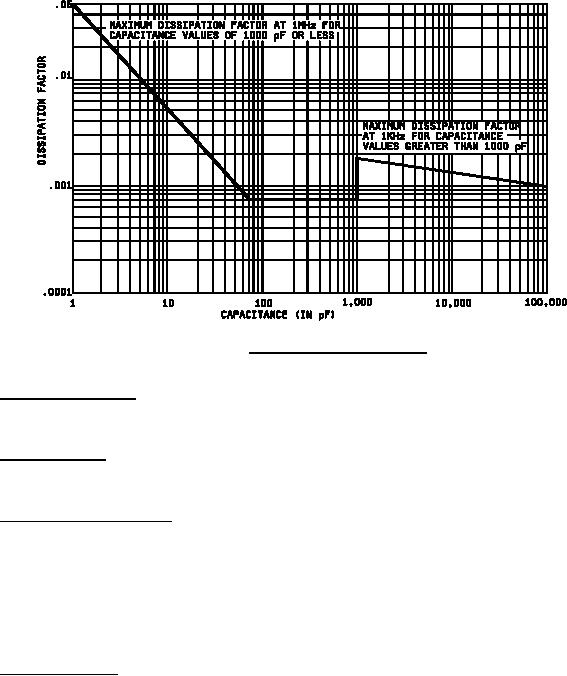

FIGURE 2. Capacitance value versus DF.

3.16 Shock, specified pulse. When capacitors are tested as specified in 4.7.12, there shall be no intermittent

contacts of 0.5 ms or greater duration, or momentary arcing, or other indication of breakdown, nor shall there be any

open-circuiting or short-circuiting or evidence of mechanical damage.

3.17 Terminal strength. When capacitors are tested as specified in 4.7.13, the terminals shall not loosen or

rupture and no other damage shall result. Chipping of the resinous coating on the leads, in the "R" dimension area

only (see 3.1), shall not be considered a failure.

3.18 Resistance to soldering heat. When tested as specified in 4.7.14, capacitors shall meet the following

requirements:

a. IR: Shall not be less than the initial requirement (see 3.9).

b. Cap: The capacitance change shall not exceed ±5 percent or ±5 pF, whichever is greater, from the initial

measurement.

c. DF: Shall not exceed initial requirement.

3.19 Moisture resistance. When tested as specified in 4.7.15, capacitors shall meet the following requirements:

a. DWV: As specified in 3.6.

b. IR: Shall be not less than 25 percent of the initial requirement (see 3.9).

c. Cap: The capacitance change shall not exceed 1 percent or 1 pF, whichever is greater, from the reference

measurement (see 4.3.2.1).

d. DF: Shall not exceed 150 percent of the initial requirement specified in 3.11.

e. Visual examination: No visible evidence of deterioration, permanent damage to the leads or case, nor

corrosion on the leads.

7

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business