MIL-PRF-39001E

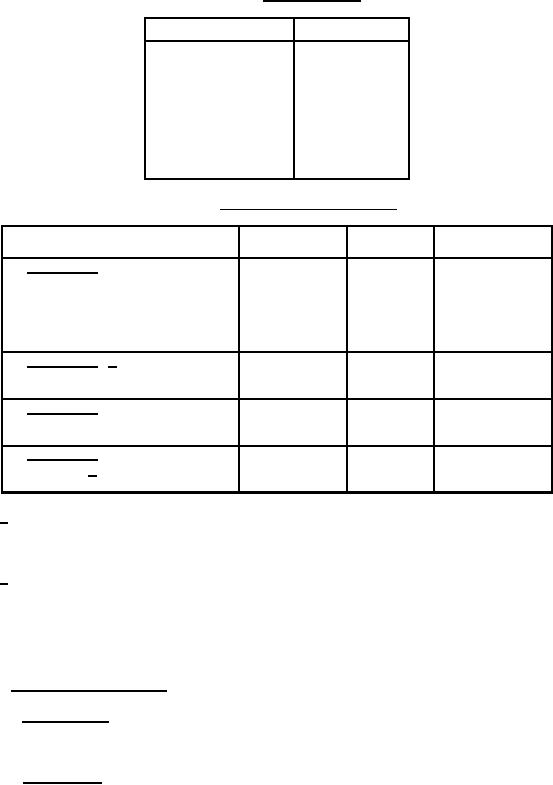

TABLE IX. Sampling plans.

Lot size

Sample size

1-

150

13

151 -

280

20

281 -

500

29

501 - 1,200

34

1,201 - 3,200

42

3,201 - 10,000

50

10,001 - 35,000

60

35,001 - 150,000

74

150,000 - 500,000

90

TABLE X. Group A inspection (ER only).

Requirement

Test method

Sample

Inspection

paragraph

paragraph

procedure

Subgroup 1

High voltage stabilization

4.7.3

Dielectric withstanding voltage

4.7.2

Insulation resistance (at 25C)

4.7.5

100% inspection

Capacitance

4.7.6

Dissipation factor

4.7.7

Subgroup 2 1/

Visual and mechanical examination

(including dimensions)

See table IX

Subgroup 3

Insulation resistance (at 125C)

4.7.5.2

20 samples

0 failures

Subgroup 4

Solderability 2/

4.7.8

5 samples

0 failures

1/ Marking defects are based on visual inspection only and shall be charged only for illegible,

incomplete, or incorrect marking. Any subsequent electrical defects shall not be used as a

basis for determining marking defects.

2/ The manufacturer may request the deletion of the subgroup 4 solderability test, provided

an in-line or process control system for assessing and assuring the solderability of leads

can be validated and approved by the qualifying activity. Deletion of the test does not

relieve the manufacturer from meeting this test requirement in case of dispute. If the

design, material, construction, or processing of the part is changed, or if there are any

quality problems, the qualifying activity may require resumption of the test.

4.6.1.2.2.4 Subgroup 4 (solderability).

4.6.1.2.2.4.1 Sampling plan. Five samples shall be selected randomly from each inspection lot and subjected to

the solderability test. The manufacturer may use electrical rejects from the subgroup 1 screening test for all or part

of the samples to be used for solderability testing. If there are one or more defects, the lot shall be rejected.

4.6.1.2.2.4.2 Rejected lots. In the event of one or more defects, the inspection lot is rejected. The manufacturer

may use one of the following options to rework the lot:

a. Each production lot that was used to form the failed inspection lot shall be individually submitted to the

solderability test as required in 4.6.1.2.2.4.1. Production lots that pass the solderability test are available for

shipment. Production lots failing the solderability test can be reworked only if submitted to the solder dip

procedure in 4.6.1.2.2.4.2b.

13

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business