MIL-DTL-3965H

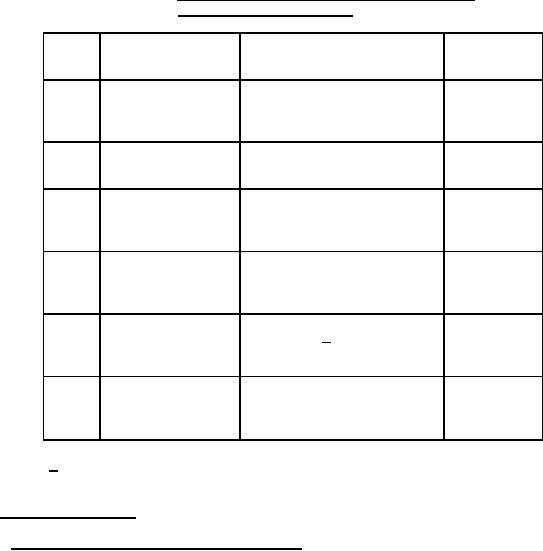

TABLE X. Temperature and measurements for stability tests

at low and high temperatures.

Test

Step

Temperature

Measurement

paragraph

4.7.5

DC leakage

+25°C

1

4.7.6

Capacitance

4.7.7

Dissipation factor

-55°C +0°C, -3°C

2

Impedance

4.7.17.1

Capacitance

4.7.6

4.7.5

DC leakage

+25°C

4.7.6

Capacitance

3

4.7.7

Dissipation factor

DC leakage

4.7.5

+85°C +6°C, -0°C

4

Capacitance

4.7.6

Dissipation factor

4.7.7

DC leakage 1/

4.7.5

+125°C +7°C, -0°C

Capacitance

5

4.7.6

Dissipation factor

4.7.7

4.7.5

DC leakage

+25°C

4.7.6

Capacitance

6

4.7.7

Dissipation factor

1/ During this measurement, derated voltage (see 3.1) shall be applied.

4.7.18 Life at 85°C (see 3.22).

4.7.18.1 2,000-hour (qualification inspection) (see 3.22.1). Capacitors shall be tested in accordance with method

108 of MIL-STD-202. The following details and exceptions shall apply:

a.

Distance of temperature measurements from specimens: Not applicable.

b.

Method of mounting: Wire-lead terminal capacitors shall be mounted by their terminals; all other capacitors

shall be mounted by normal mounting means.

Test temperature and tolerance: +85°C +6°C, -0°C.

c.

d.

Operating conditions: DC rated voltage (see 3.1) shall be applied gradually (not to exceed 5 minutes either

by a slow build-up of the voltage or through a resistor which shall be shorted out within 5 minutes). Voltage

shall be applied continuously except for measurement periods. The impedance of the voltage source, as

seen from the terminals of each capacitor, shall not exceed 10 ohms. Storage batteries (or an electronic

power supply) capable of supplying at least 100 milliamperes when a capacitor is shorted out shall be used.

For nonpolarized capacitors, the voltage shall be reversed every 125 ±10 hours.

e.

Test condition: F (2,000) +72 -0 hours).

26

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business