MIL-C-5G

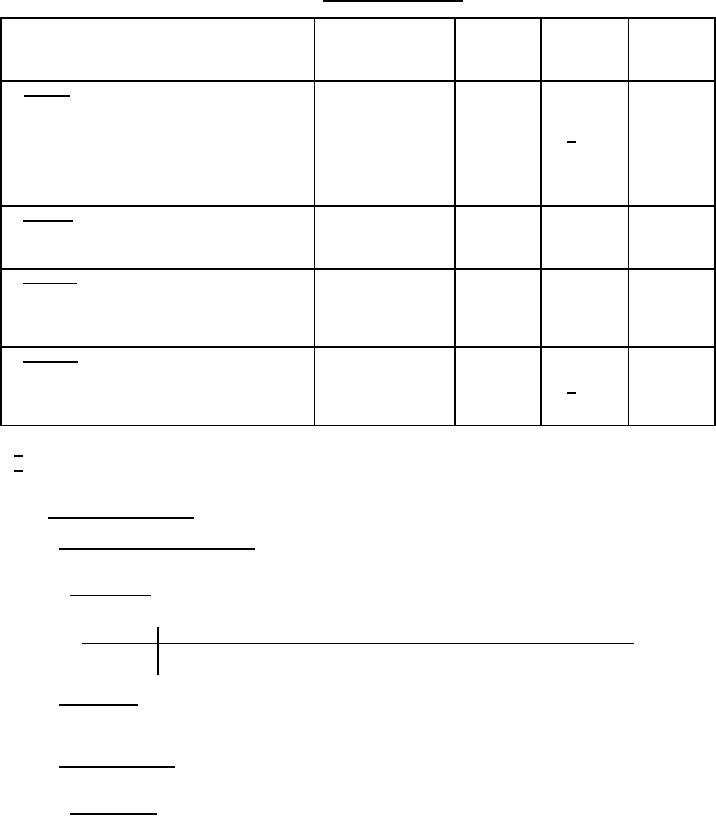

TABLE VII. Qualification inspection.

Examination or test

Requirement

Method

Number of

Number of

paragraph

paragraph

sample

defectives

units to be

allowed

inspected

Group I

Visual and mechanical examination

1/ 43

Dielectric withstanding voltage

1

Barometric pressure

Insulation resistance

Dissipation factor

Capacitance

Group II

High frequency vibration

12

1

Thermal shock and immersion

4.6.8.1 to

Group III

Shock (specified pulse)

Solderability

12

1

Terminal strength

Moisture resistance

Group IV

Temperature coefficient and capacitance drift

4.6.13.1 to

2/ 18

1

Low-temperature storage and life

4.6.14 and

1/ One additional specimen is included to permit substitution for the allowable defective in group I.

2/ Only 12 specimens are to be subjected to the temperature-coefficient and capacitance-drift test, 6 of which shall

be of the low capacitance sample units when single style qualification is sought.

4.5 Conformance inspection.

4.5.1 Inspection of product for delivery. Inspection of product for delivery shall consist of group A and group B

inspection.

4.5.1.1 Inspection lot. An inspection lot shall consist of capacitors in one or more styles. The sample selected

from the lot shall be representative of the styles in the lot. Styles may be grouped as follows:

Group

Styles

1

CM04, CM05, CM06, CM07, CM08, CM09, CM10, CM11, CM12, and CM13

2

CM15

4.5.2 Rejected lots. If an inspection lot is rejected, the supplier may withdraw the lot, rework it to correct the

defects, or screen out defectives and resubmit for re-inspection. Such lots shall be kept separate from new lots and

shall be clearly identified as re-inspected lots. Rejected lots shall be inspected, using tightened inspection.

4.5.3 Group A inspection. Group A inspection shall consist of the examinations and tests specified in table VIII, in

the order shown.

4.5.3.1 Sampling plan. A sample of parts shall be randomly selected in accordance with table IX. If one or more

defects are found, the lot shall be rescreened and defects removed. After screening and removal of defects, a new

sample of parts shall be randomly selected in accordance with table IX. If one or more defects are found in the

second sample, the lot shall be rejected and shall not be supplied to this inspection.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business