MIL-C-5G

In the event that there is no production of a single style device during a reporting period and the manufacturer is

listed for more than one style on the QPL, the manufacturer shall verify they still have the capabilities and facilities

necessary to produce that product. If during three consecutive reporting periods there has been no production of a

given style, the manufacturer may be required, at the discretion of the qualifying activity, to submit a representative

product of that style to testing.

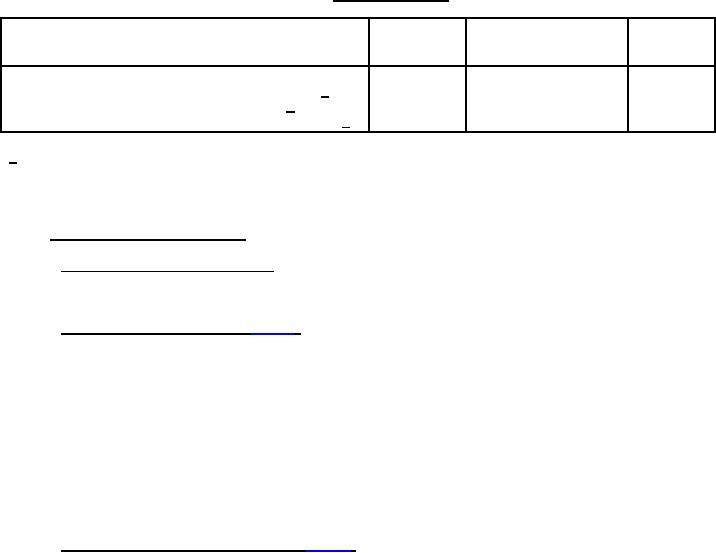

TABLE X. Group B inspection.

Test

Requirement

Method paragraph

Sample

paragraph

procedure

Insulation resistance (at high ambient temperature) 1/

5 samples

Temperature coefficient and capacitance drift 1/

4.6.13.2 thru 4.6.13.2.2

0 failures

Low-temperature storage and life (performance check) 1/

1/ If the manufacturer can demonstrate that this test has been performed five consecutive times with zero failures,

the frequency of this test, with the approval of the qualifying activity, can be performed every two years. If the

design, material, construction, or processing of the part is changed, or if there are any quality problems or failures,

the qualifying activity may require resumption of the original test frequency.

4.6 Methods of examination and test.

4.6.1 Visual and mechanical examination. Capacitors shall be examined to verify that the materials, design,

construction, physical dimensions, marking, and workmanship are in accordance with the applicable requirements

4.6.2 Dielectric withstanding voltage (see 3.5). Capacitors shall be tested in accordance with

method 301 of MIL-STD-202. The following details shall apply:

a. Magnitude and nature of test voltage: 200 percent of the dc working voltage (see 3.1).

b. Duration of application of test voltage: Not less than 1 second nor more than 5 seconds. The duration of the

test shall begin when 95 percent of the test potential is reached.

c. Points of application of test voltage: Between terminals.

d. Limiting value of surge current: Shall not exceed 5 milliamperes (mA).

e. Examinations after test: Capacitors shall be examined for evidence of damage, arcing, and breakdown.

4.6.3 Barometric pressure (Qualification only) (see 3.6). Capacitors shall be tested in accordance with

method 105 of MIL-STD-202. The following details and exceptions shall apply:

a. Method of mounting: Not applicable.

b. Test condition: Reduced pressure as specified (see 3.1).

c. Tests during subjection to reduced pressure: A test potential as specified (see 3.1) shall be applied between

the terminals for not less than 1 second nor more than 5 seconds.

d. Examinations after test: Capacitors shall be examined for evidence of damage, arcing, and breakdown.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business