MIL-C-25F

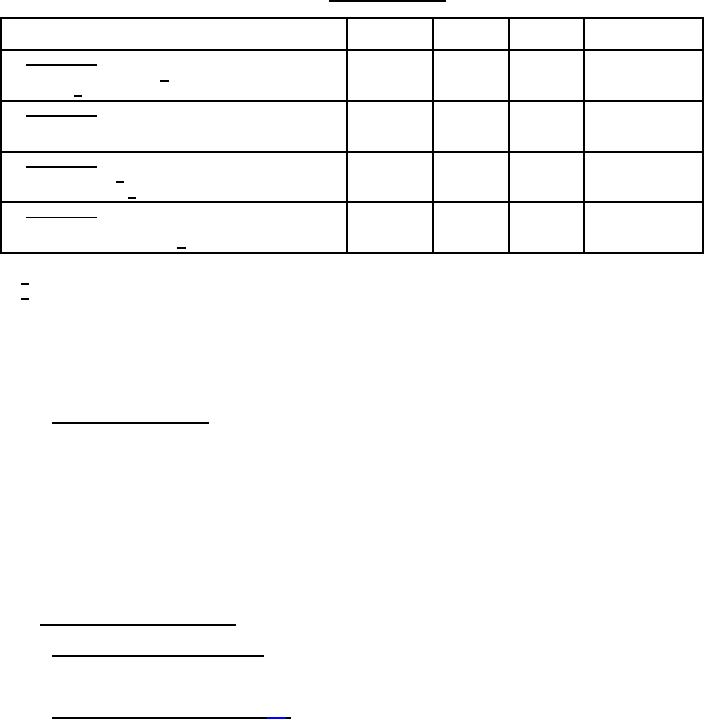

TABLE IX. Group C inspection

Requirement Method

Number of

Number of

Inspection

paragraph paragraph samples defectives allowed

Subgroup 1

Vibration (low frequency) 1/

5

0

Immersion 2/

Subgroup 2

Insulation resistance (at high ambient test temperature)

5

0

Life

Subgroup 3

Terminal strength 2/

Moisture resistance 2/

6

1

Subgroup 4

Low ambient temperature and capacitance change

6

1

Salt atmosphere (corrosion) 2/

1/ The time period for vibration is a minimum of once every 24 months.

2/ If the manufacturer can demonstrate that this test has been performed five consecutive times with zero

failures, this test, with the approval of the qualifying activity, can be deleted. The manufacturer, however, shall

perform this test every three years after the deletion as part of long term design verification. If the design,

material, construction, or processing of the part is changed, or if there are any quality problems, the qualifying

activity may require resumption of the specified testing. Deletion of testing does not relieve the manufacturer

from meeting the test requirements in case of dispute.

4.5.5 Verification of qualification. Every 12 months, the manufacturer shall provide verification of qualification to

the qualifying activity. Continuation of qualification shall be based on meeting the following requirements:

a. Group A inspection.

b. Periodic group C inspection.

In the event that there is no production of a single style device during a reporting period and the manufacturer is listed

for more than one style on the QPL, a report shall be submitted certifying that the manufacturer still has the

capabilities and facilities necessary to produce that product. If during three consecutive reporting periods there has

been no production of a given style, the manufacturer may be required, at the discretion of the qualifying activity, to

submit a representative product of that style to testing.

4.6 Methods of examination and test.

4.6.1 Visual and mechanical examination. Capacitors shall be examined to verify that the materials, design,

construction, physical dimensions, marking, and workmanship are in accordance with the applicable requirements

4.6.2 Dielectric withstanding voltage (see 3.5). Unless otherwise specified (see 3.1), capacitors shall be tested in

accordance with method 301 of MIL-STD-202, and as detailed in table X. The surge current shall be limited to

between 5 milliamperes and 1 ampere. When necessary, a suitable current-limiting resistor shall be inserted into the

circuit. At least 95 percent of the specified potential shall appear across the terminals of the capacitor prior to and

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business