MIL-C-25F

4.5.2.2 Rejected lots. If an inspection lot is rejected for subgroup 2, the supplier may withdraw the lot, rework it to

correct the defects, or screen out the defective units, as applicable and reinspect. If one or more defects are found

during this reinspection, the lot shall be rejected and shall not be supplied to this specification. Reinspected lots shall

be separated from new lots and shall be clearly identified as reinspected lots.

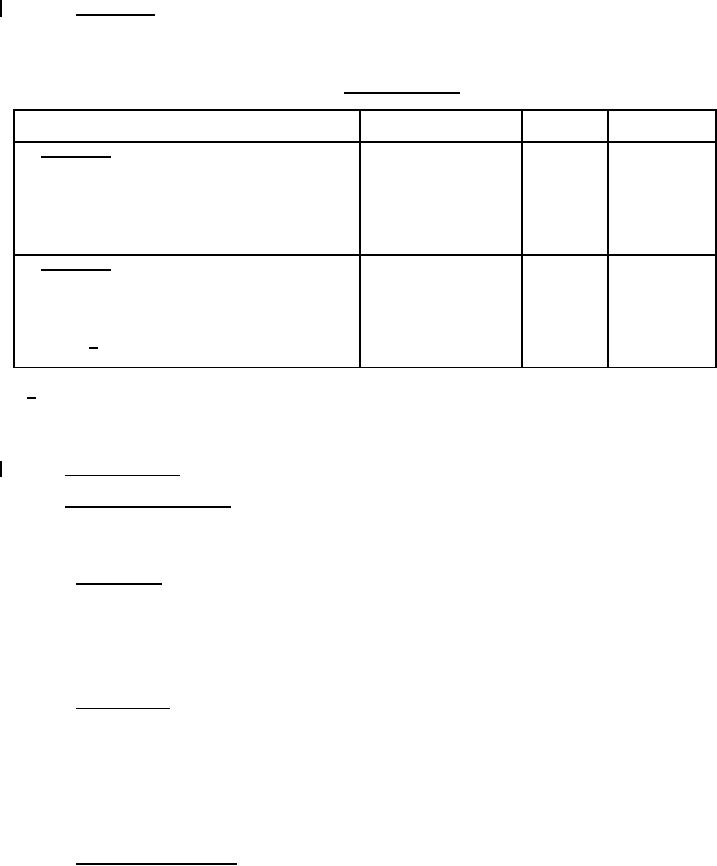

TABLE VIII. Group A inspection.

Test method

Sampling

Inspection

Requirement paragraph

paragraph

procedure

Subgroup 1

Thermal shock

Seal

Dielectric withstanding voltage

100 percent

Insulation resistance (at +25°C)

Capacitance

Dissipation factor

Subgroup 2

Visual mechanical examination:

Materials

Body dimensions

13 samples

Design and construction (other than body dimensions)

0 failures

Marking 1/

Workmanship

1/ Marking defects are based on visual examination and shall be charged only for illegible, incomplete, or

incorrect marking. Any subsequent electrical defects shall not be used as the basis for determining

marking defects.

4.5.3 Group B inspection. Group B inspection is not required.

4.5.4 Periodic group C inspection. Periodic group C inspection shall consist of the tests specified in table IX in the

order shown, and shall be performed on sample units selected from lots that have passed group A inspection.

Except where the results of this inspection show noncompliance with the applicable requirements (see 4.5.4.2),

delivery of products which have passed group A shall not be delayed pending the results of this periodic inspection.

4.5.4.1 Sampling plan. For subgroup 1 and subgroup 2, sample units shall be taken from production every six

months. The time period for vibration shall be a minimum of every 24 months. For subgroup 3 and subgroup 4,

sample units shall be taken from production every year. A different set of sample units shall be selected for each

subgroup. Sample units of the same style (any one style covered by a specification sheet may be representative of

any other style specified therein; see table A-I) shall be selected in each characteristic, irrespective of voltage and

capacitance. These sample units may be in any capacitance tolerance. If the number of defectives exceeds those

allowed in table IX, the sample shall be considered to have failed.

4.5.4.2 Noncompliance. If a sample fails to pass group C inspection, the supplier shall take corrective action on

the materials or processes or both, as warranted, and on all units of product which can be corrected and which were

manufactured under essentially the same conditions, with essentially the same materials and processes, and which

are considered subject to the same failure. Acceptance of the product shall be discontinued until corrective action

acceptable to the Government has been taken. After the corrective action has been taken, additional sample units

shall be subjected to group C inspection (all inspections, or the inspections which the sample failed, at the option of

the Government). Group A inspection may be reinstituted; however, final acceptance shall be withheld until the group

C inspection has shown that the corrective action was successful. In the event of failure after reinspection,

information concerning the failure and the corrective action taken shall be furnished to the contracting officer.

4.5.4.3 Disposition of sample units. Sample units that have been subjected to group C inspection shall not be

delivered on the contract or order.

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business