MIL-C-25F

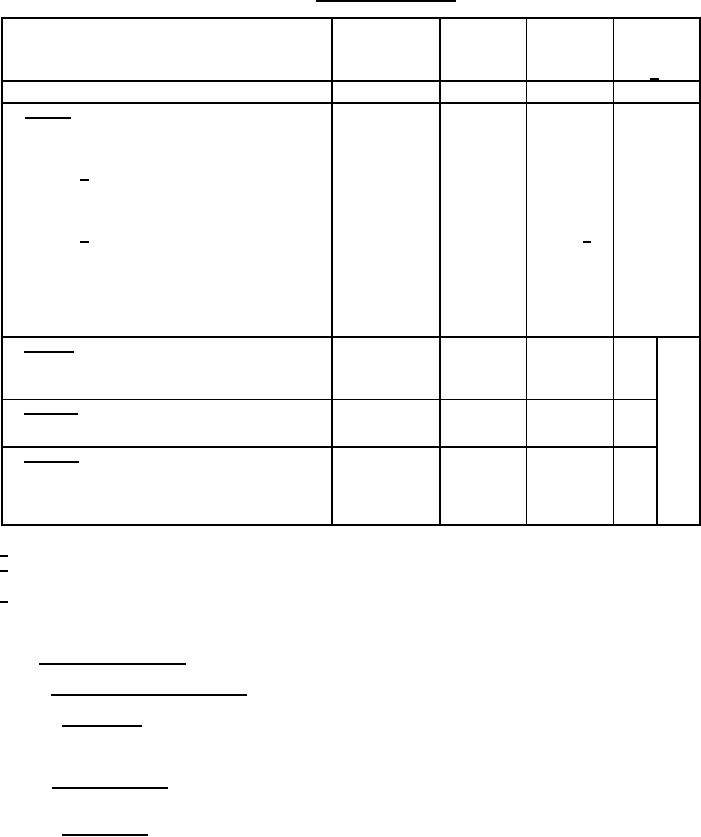

TABLE VII. Qualification inspection.

Number of

Number of

Requirement

Method

sample

defectives

Examination or test

paragraph

paragraph

units to be

allowed

inspected

1/

Flashpoint of impregnant or filling compound

See A.2.1.3

0

Group I

Visual and mechanical examination (internal):

Material, design, construction, and physical

dimensions

2

0

Marking 2/

Workmanship

Visual and mechanical examination (external):

Marking 2/

25 3/

1

Workmanship

Dielectric withstanding voltage

Insulation resistance

Capacitance

Dissipation factor

Barometric pressure

Group II

Vibration (low frequency)

6

1

Salt atmosphere

Thermal shock and immersion

Group III

1

Terminal strength

6

1

Moisture resistance

Group IV

Seal

12

1

Low ambient temperature and capacitance change

with temperature

Life

1/ A specimen having one or more defects shall be considered as one defective.

2/ Marking defects are based on visual examination only and shall be charged only for illegible, incomplete, or

incorrect marking. Any subsequent electrical defects shall not be used as a basis for determining marking defects.

3/ One additional specimen is included in each sample of 27 specimens to permit substitution for the allowable

defective in group I.

4.5 Conformance inspection.

4.5.1 Inspection of product for delivery. Inspection of product for delivery shall consist of group A inspection.

4.5.1.1 Inspection lot. An inspection lot, as far as practicable, shall consist of capacitors grouped by style and

characteristics, as specified (see 3.1). Capacitors of different characteristics having the same impregnant shall be

considered as capacitors of the same characteristic.

4.5.2 Group A inspection. Group A inspection shall consist of the examinations and tests specified in table VIII, in

the order shown.

4.5.2.1 Sampling plan. The sampling plan shall be performed on an inspection lot basis as specified in table VIII.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business