MIL-PRF-87164A

4.6.3.1.2 Subgroup 2. Subgroup 2 tests of Table V shall be performed on a sample selected in accordance with

table VI based on the size of the lot. In the event of one or more failures, the lot shall be rejected and not supplied to

this specification. The manufacturer has the option of 100 percent screening the lot for the quality characteristic

found defective in the sample and any defective unit removed. A new sample of parts shall then be randomly

selected in accordance with table VI. If one or more defects are found in the second sample, the lot shall be rejected

and shall not be supplied to this specification.

4.6.3.1.3 Subgroup 4 and subgroup 5. The number of sample units required by table V shall be performed on

sample units from lots that have been subjected to and have passed subgroup 1 and subgroup 2 tests.

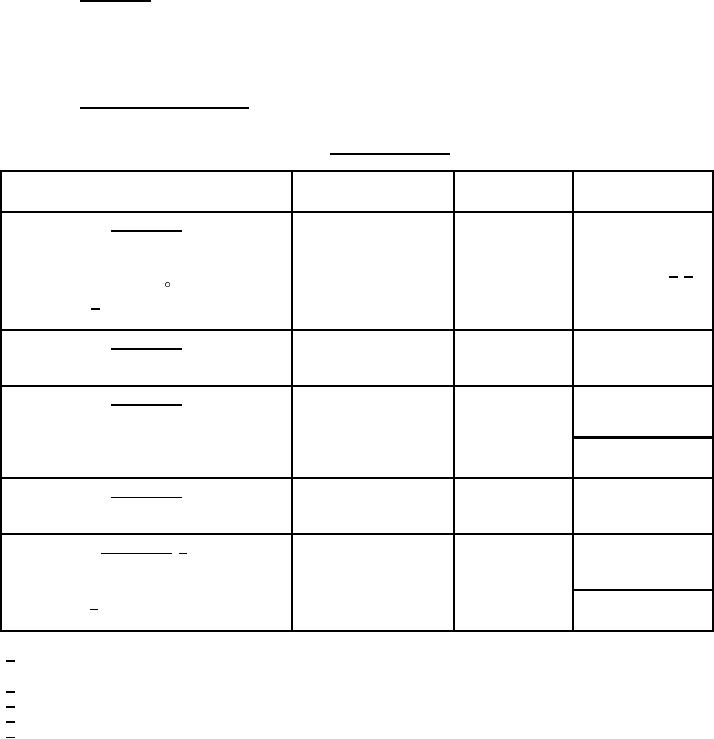

TABLE V. Group A inspection.

Inspection

Requirement

Method

Sampling

Paragraph

Paragraph

Procedure

Subgroup 1

4.7.11.1

3.15

Thermal shock and immersion

4.7.7

3.11

High voltage stabilization

100 percent 2/ 3/

4.7.2

3.6

Dielectric withstanding voltage

4.7.4.1

3.8.1

Insulation resistance (+25 C)

4.7.5

3.9

Capacitance 1/

4.7.6

3.10

Dissipation factor

Subgroup 2

Visual and mechanical examination

3.1, 3.4 to 3.5.2 incl

4.7.1

see table VI

3.24 to 3.25 incl

Subgroup 3

Insulation resistance at +25°C and +125°C

3.8

4.7.4

20 samples

0 failures

Moisture resistance

3.18

4.7.14

20 samples

1 failure

Subgroup 4

Life test (250 hours accelerated)

3.19

4.7.15.2.1

20 samples

0 failures

Subgroup 5 4/

Resistance to solvents

3.21

4.7.17

5 samples

0 failures

Solderability 5/

3.12

4.7.8

10 samples

1 failure

1/ Capacitance values outside the initial limits by 1 percent or 1 pF, whichever is greater, shall be used for PDA

lot rejection.

2/ Dissipation factor greater than 130 percent of the initial limit shall be used for PDA lot rejection.

3/ All capacitors delivered to this specification shall meet the nominal requirements.

4/ The same samples can be used for resistance to solvents and solderability.

5/ The manufacturer may request the deletion of the subgroup 5 solderability test, provided an in-line or

process control system for assessing and assuring the solderability of leads can be validated and approved

by the qualifying activity. Deletion of the test does not relieve the manufacturer from meeting this test

requirement in case of dispute. If the design, material, construction, or processing of the part is changed, or

if there are any quality problems, the qualifying activity may require resumption of the test.

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business