MIL-PRF-83421E

4.3.1 Reference measurements. When requirements are based on comparative measurements made before and

after conditioning, the reference measurement shall be considered the last measurement made at +25°C ±3°C prior

to beginning of conditioning. Unless reference measurements have been made within 30 days prior to the beginning

of conditioning, they shall be repeated.

4.3.2 Power supply. The power supply used for life testing shall have a regulation of ±2 percent or less of the

specified test voltage.

4.4 Qualification inspection. Qualification inspection shall be performed at a laboratory acceptable to the qualifying

activity (see 6.4) on sample units produced with equipment and procedures normally used in production.

4.4.1 Sample size. The number of capacitors to be subjected to qualification inspection shall be as specified in

appendix A of this specification.

4.4.2 Inspection routine. Sample units shall be subjected to the qualification inspection specified in table II, in the

order shown. All sample units, including those sample units required for group X testing (when applicable), shall be

subjected to the inspections of group I (when applicable) and group II. The sample units, with the exception of group

X samples (when applicable) shall then be divided into the eight remaining groups as specified in table II, and

subjected to the tests for their particular group.

Sample units which have been selected to be submitted to the life test shall be divided into two groups; one group

shall be subjected to the accelerated condition and the other group to the rated condition. The decision as to whether

or not the product is to be included on the qualified products list shall be made at the conclusion of the 2,000-hour life

test.

4.4.3 Failures. Failures in excess of those allowed in table II shall be cause for refusal to grant qualification

approval.

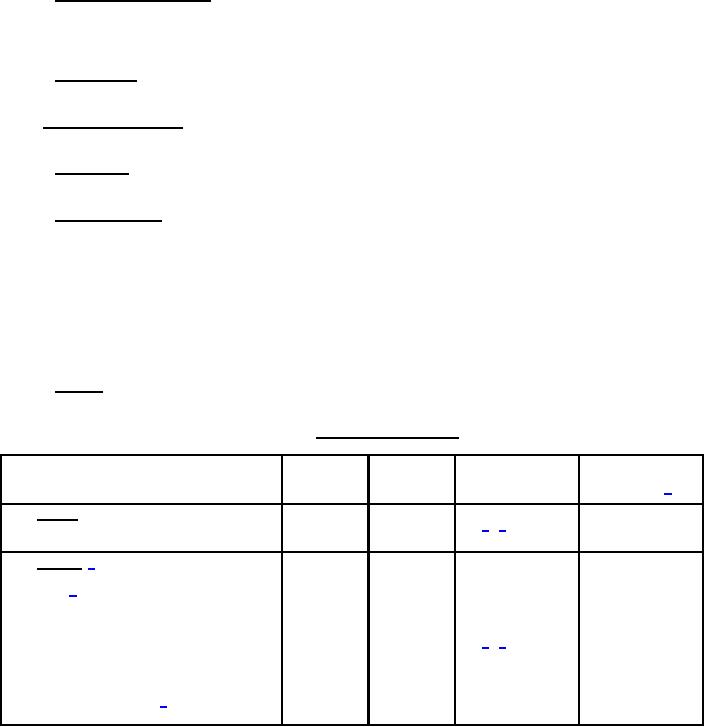

TABLE II. Qualification inspection.

Test

Number of sample

Number of defects

Requirement

method

units to be

Inspection

permitted 1/

paragraph

paragraph

inspected

Group I

2/ 3/ 89 min

NA

Burn-in (when specified, see 3.1)

Dielectric absorption (when specified, see 3.1)

Group II 4/

Visual and mechanical examination

Marking 5/

Workmanship (external)

Thermal shock

Seal

NA

2/ 3/ 89 min

Dielectric withstanding voltage

Insulation resistance

Capacitance

Dissipation factor

Equivalent series resistance 6/

Barometric pressure (reduced)

See footnotes at end of table.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business