MIL-PRF-83421E

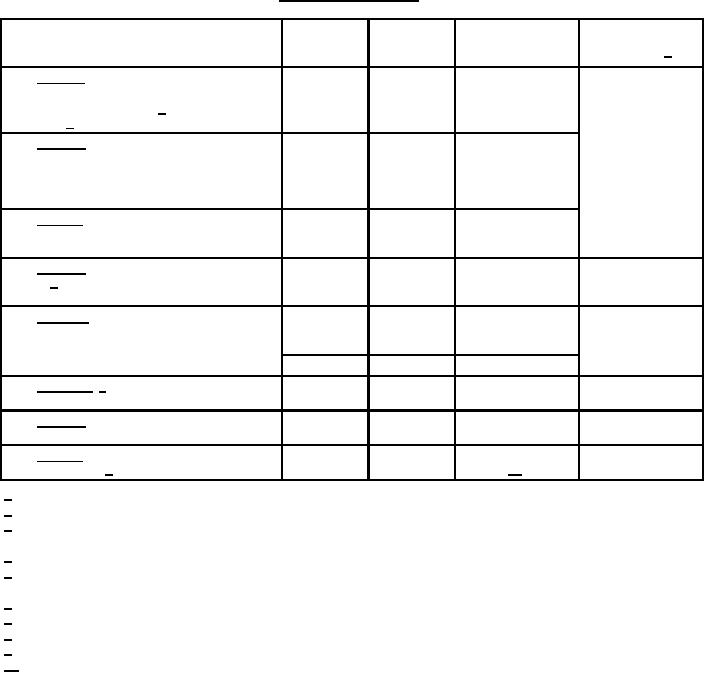

TABLE II. Qualification inspection - Continued.

Test

Number of sample

Number of defects

Requirement

method

units to be

Inspection

permitted 1/

paragraph

paragraph

inspected

Group III

Vibration, high frequency

6

Salt atmosphere (corrosion) 7/

Immersion 7/

Group IV

Solderability

6

1

Shock (specified pulse)

Resistance to soldering heat

Moisture resistance

Group V

6

Terminal strength

Low temperature life

Group VI

4

1

Fungus 8/

4

Resistance to solvents

Group VII

33

Temperature coefficient

1

Life (accelerated conditions)

Life (rated conditions)

30

Group VIII 2/

24

1

AC conditioning

Group IX

1

0

Flash point of impregnant (when specified, see 3.1)

Group X (when applicable)

10/

0

Vibration, random 9/

1/ A sample unit having one or more defects shall be considered as a single defect.

2/ Group VIII for styles CRH11, CRH12, and CRH13 only. Group I and group II samples shall be 113 minimum.

3/ This total shall be determined by the number of capacitors tested for random vibration in group X. Additional

samples over the minimum should be included to allow for any failures.

4/ Nondestructive tests.

5/ Marking defects are based on visual inspection only and shall be charged only for illegible, incomplete, or incorrect

marking. Any subsequent electrical defects shall not be used as a basis for determining marking defects.

6/ Equivalent series resistance applicable to styles CHR11, CHR12, and CHR13.

7/ One-half of the sample units shall be tested with the insulating sleeves removed.

8/ Certification of fungus resistance may be substituted for testing.

9/ Unless otherwise specified, random vibration is optional (see 3.1).

10/ When applicable, an additional three sample units of the longest case length of each diameter for which

qualification is sought shall be required for group X testing.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business