MIL-PRF-83421E

6.2 Acquisition requirements. Acquisition documents must specify the following:

a. Title, number, and date of this specification, the applicable specification sheet, and the complete PIN (see

3.1).

b. Packaging requirements (see 5.1).

6.3 Solder dip (retinning). If retinning (hot solder dip) of the leads is required, see 3.5.3.1.

6.4 Qualification. With respect to products requiring qualification, awards will be made only for products which are,

at the time of award of contract, qualified for inclusion in the Qualified Products List QPL whether or not such

products have actually been so listed by that date. The attention of the contractors is called to these requirements,

and manufacturers are urged to arrange to have the products that they propose to offer to the Federal Government

tested for qualification in order that they may be eligible to be awarded contracts or orders for the products covered

by this specification. Information pertaining to qualification of products may be obtained from DLA Land and

Maritime, ATTN: VQP, PO Box 3990, Columbus, OH 43218-3990, or by e-mail to vqp.chief@dla.mil. An online

listing of products qualified to this specification may be found in the Qualified Products Database (QPD) at

6.4.1 Copies of SC-6. Copies of SD-6, "Provisions Governing Qualification", are available online at

https://assist.daps.dla.mil/quicksearch/ or from the Standardization Document Order Desk, 700 Robbins Avenue,

Building 4D, Philadelphia, PA 19111-5094.

6.5 Subject term (key word) listing.

Capacitance

Dissipation factor

Insulation resistance

6.6 PIN example. See 1.2.1 for details.

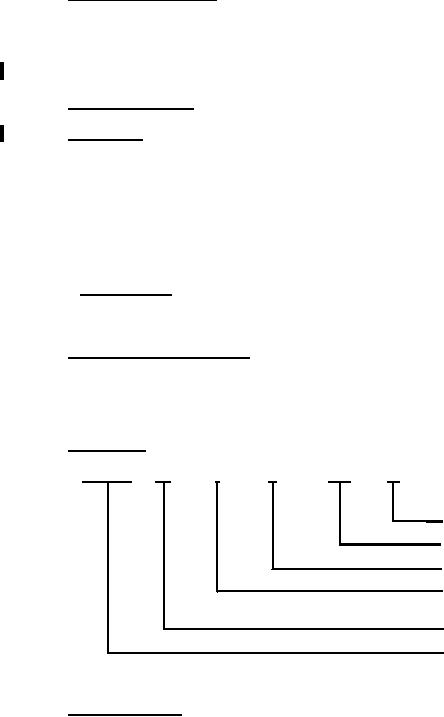

M83421/

01

-

1

123

M

Single letter designating FRL (M, P, R, and S)

Nonsignificant dash number

Single digit designating style

"-" for standard product or

"H" for random vibration option

Slash sheet number

Performance specification number

6.7 Tin whisker growth. The use of alloys with tin content greater than 97 percent, by mass, may exhibit tin

whisker growth problems after manufacture. Tin whiskers may occur anytime from a day to years after manufacture

and can develop under typical operating conditions, on products that use such materials. Conformal coatings applied

over top of a whisker-prone surface will not prevent the formation of tin whiskers. Alloys of 3 percent lead, by mass,

have shown to inhibit the growth of tin whiskers. For additional information on this matter, refer to ASTM-B545

(Standard Specification for Electrodeposited Coatings of Tin).

25

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business