MIL-PRF-20M

(2) If the 200 sample units (or 100 percent of the lot, whichever is less) fail group A, subgroup 1

post-electrical tests, these tests shall be performed on 100 percent of the lot. The lot must meet the 5

percent PDA requirements as specified in 4.6.1.2.1.1. If the PDA requirements are not met, the lot shall

be considered rejected and shall not be furnished against the requirements of this specification. If the

PDA requirements are met, 5 sample units shall be subjected to the solderability testing criteria of

4.6.1.2.1.3.3 Disposition of samples. The solderability test is considered a destructive test and samples submitted

to the solderability test shall not be supplied on the contract or order.

4.6.1.2.1.4 Subgroup 4 (FRL "S" only). The subgroup 4 test shall be performed on all capacitors offered for

inspection. Capacitors not meeting the inspection criteria shall be removed from the production lot and shall not be

supplied to this specification.

4.6.1.2.1.5 PPM calculations. The manufacturer shall establish a ppm system in accordance with 3.3.2 for

assessing and calculating average outgoing quality of capacitors. A ppm rate combining capacitance, dissipation

factor, insulating resistance (IR) (25°C), and DWV shall be assessed for lots that have passed the group A inspection.

The manufacturer's ppm system shall also address rectification procedures for lots failing ppm assessment. Data

from the rectification process shall not be used to calculate ppm.

4.6.1.2.2 Non-ER capacitors.

4.6.1.2.2.1 Subgroup 1 and subgroup 2 tests.

4.6.1.2.2.1.1 Sampling plan. The sampling plan for subgroup 1 and subgroup 2 shall be as specified in table VII.

4.6.1.2.2.1.2 Rejected lots. If an inspection lot for subgroup 1 or subgroup 2 is rejected, the manufacturer may

rework the inspection lot to correct the defects, or screen out the defective units and resubmit the lot for reinspection.

If one or more defects are found during this reinspection, the lot shall be rejected and shall not be supplied to this

specification. Such lots shall be separated from new lots, and shall be clearly identified as reinspected lots.

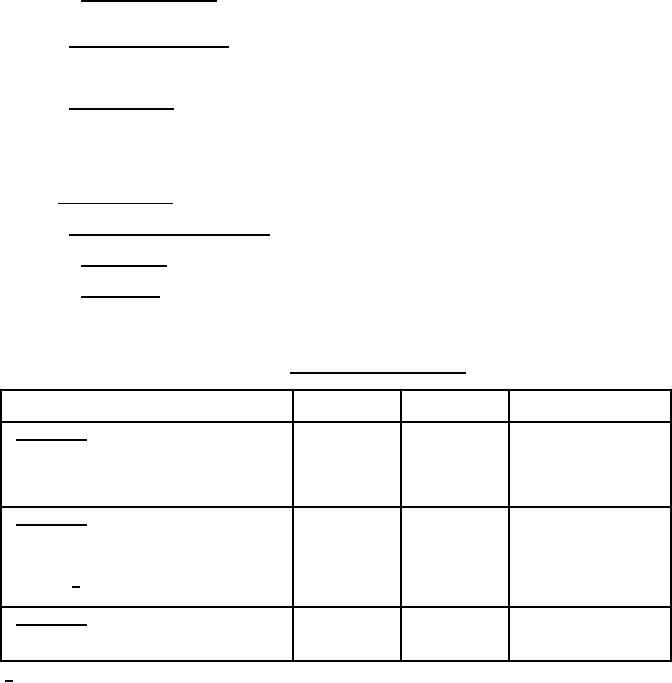

TABLE VII. Group A inspection (Non-ER).

Requirement

Test method

Inspection

Sampling procedure

paragraph

paragraph

Subgroup 1

Capacitance

125 samples

Dissipation factor

0 failure

Dielectric withstanding voltage

Insulation resistance

Subgroup 2

Visual and mechanical examination:

Material

13 samples

Physical dimensions

0 failures

Marking 1/

Workmanship

Subgroup 3

Solderability

5 samples

0 failures

1/ Marking defects are based on visual examination only.

16

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business