MIL-PRF-20M

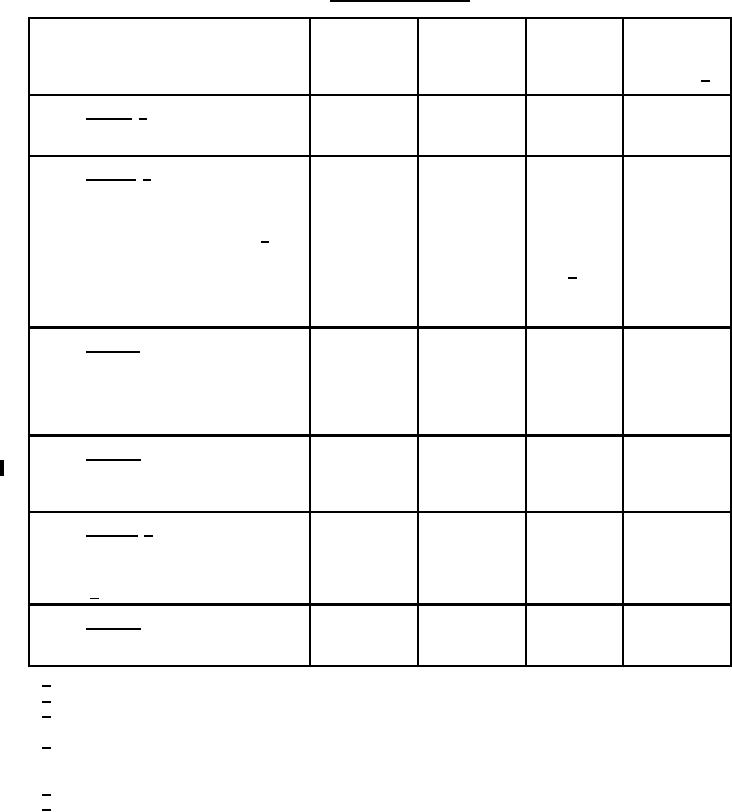

TABLE IV. Qualification inspection.

Number of

Number of

sample

Requirement

Test method

defectives

Inspection

units to be

paragraph

paragraph

permitted 1/

inspected

Group I 2/

Thermal shock and voltage conditioning

All units

Not applicable

Radiographic inspection (FRL S only)

All units

Not applicable

Group II 2/

Visual and mechanical examination:

Material, design, and construction

Workmanship

Physical dimensions and marking 3/

37 (non-ER)

1

Capacitance

49 (ER)

Dissipation factor

4/

Dielectric withstanding voltage

Barometric pressure (reduced)

Insulation resistance

Group III

Temperature coefficient and capacitance

drift

12

1

Shock, specified pulse

Vibration, high frequency

Thermal shock and immersion

Group IV

Terminal strength

Resistance to soldering heat

6

1

Moisture resistance

Group V 5/

Solderability

Marking legibility (laser marking only)

6

1

Resistance to solvents (ink marking only)

Fungus 6/

Group VI

Life (at elevated ambient temperatures)

12 (non-ER)

1

24 (ER)

1/ A sample unit having one or more defects will be charged as a single defective.

2/ Group I and group II examinations and tests are nondestructive.

3/ Marking defects are based on visual examination only and shall be charged only as illegible, incomplete, or

incorrect marking. Provisions to reject unmarked parts will also be made.

4/ One additional sample unit is included in each sample to permit substitution for the failure allowed in group II (37

sample units for non-ER styles active for new design; 31 sample units for non-ER styles inactive for new

design).

5/ Applicable to active for new design styles only.

6/ Certification of fungus resistance may be substituted for testing.

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business