MIL-PRF-20M

Production lots with greater than 5 percent to 15 percent PDA may be offered for acceptance only if the manufacturer

100 percent retests to the requirements of subgroup 1. Resubmitted lots shall be kept separate and shall be clearly

identified as resubmitted lots. If, during the 100 percent inspection, the lot requires that more than 3 percent of the

capacitors be discarded, the entire lot shall be rejected and shall not be resubmitted.

4.6.1.2.1.1.1 Manufacturer's production inspection. If the manufacturer performs tests similar to those specified in

subgroup 1 of table V as the final step of their production process, group A, subgroup 1 may be waived and the data

resulting from the manufacturer's production tests may be used instead. Authority to waive the subgroup 1 inspection

shall be granted by the qualifying activity only. The following criteria must be complied with:

a. Tests conducted by the manufacturer during production shall be clearly identical to or more stringent than that

specified for subgroup 1.

b. Manufacturer subjects 100 percent of the product supplied under this specification to their production tests.

c. The parameters measured and the failure criteria shall be the same as, or more stringent than, those

specified herein.

d. The lot rejection criterion is the same as, or more stringent than that specified herein.

e. The manufacturer shall make available all information concerning the test procedures and instrumentation

used in their production tests. This data shall be provided as part of the evaluation required for MIL-STD-790.

The manufacturer shall also make available to the Government all records of all detail test data resulting from

production tests.

f. Once approved, the manufacturer shall not change the test procedures or criteria without prior notification and

concurrence by the qualifying activity.

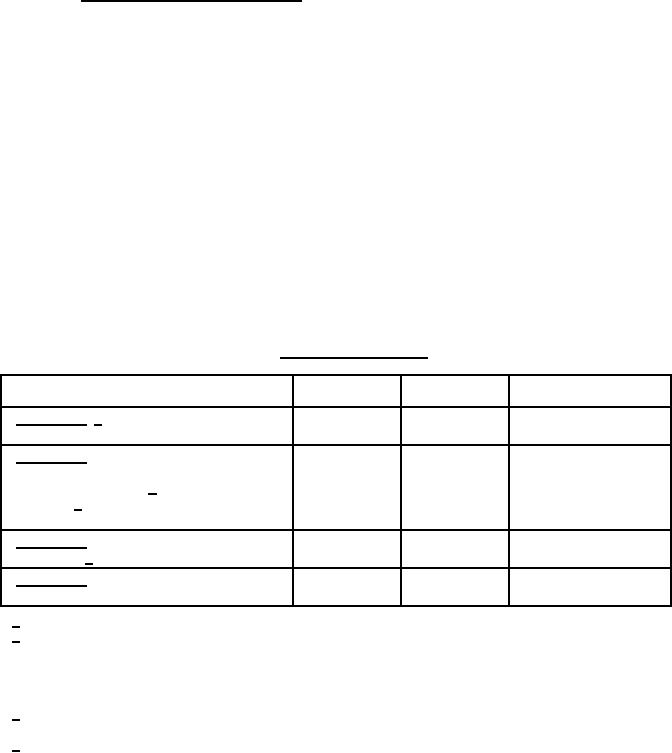

TABLE V. Group A inspection (ER).

Requirement

Test method

Inspection

Sampling procedure

paragraph

paragraph

Subgroup 1 1/

Thermal shock and voltage conditioning

100% inspection

Subgroup 2

Visual and mechanical examination, external:

Physical dimensions 2/

See table VI

Marking 3/

Workmanship

Subgroup 3

5 samples / 0 failures

Solderability 4/

Subgroup 4

100% inspection

Radiographic inspection (FRL S only)

1/ Post checks are required in accordance with 3.6.

2/ This can be eliminated if the manufacturer has demonstrated process under the SPC program (see 3.3.1),

and has been approved by the qualifying activity. If the design, material, construction, or processing of the

part is changed or, there are any quality problems, or failures, the qualifying activity may require resumption

of the specified testing. Deletion of testing does not relieve the manufacturer from meeting the test

requirement in case of dispute.

3/ Marking defects are based on visual examination only. Any subsequent electrical defects shall not be used

as a basis for determining marking defects.

4/ The manufacturer may request the deletion of the solderability test provided an in-line or process control

system for assessing and to assuring the solderability of leads can be validated and approved by the

qualifying activity. Deletion of the test does not relieve the manufacturer from meeting this test requirement.

14

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business