MIL-PRF-20M

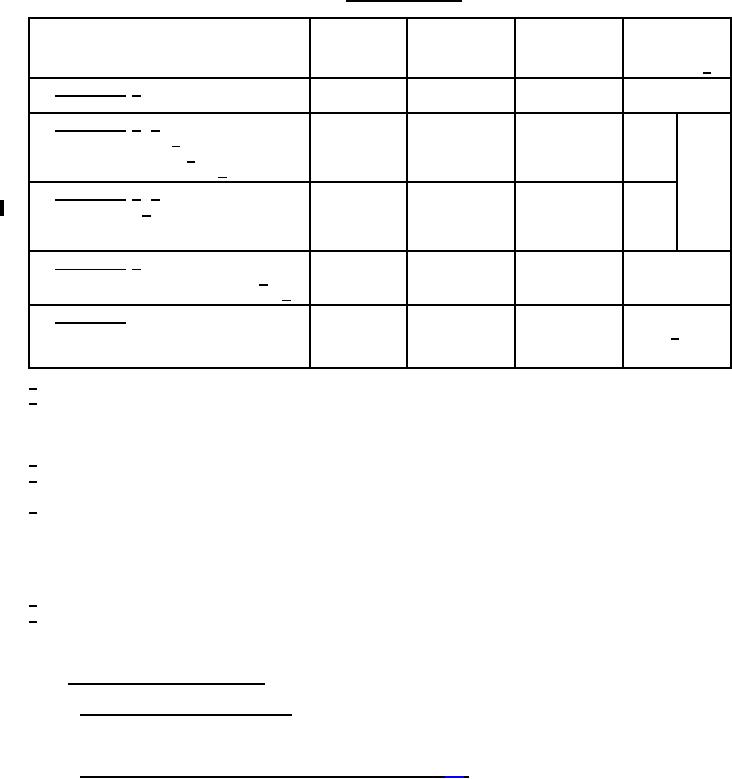

TABLE VIII. Group B inspection.

Number of

Number of

Requirement

Test method

sample units to

Inspection

defectives

paragraph

paragraph

be inspected

permitted 1/

Subgroup 1 2/

12

0

Temperature coefficient and capacitance drift

Subgroup 2 3/ 4/

Shock, specified pulse 5/

12

1

Vibration, high frequency 5/

Thermal shock and immersion 5/

1

Subgroup 3 3/ 4/

Terminal strength 5/

1

Resistance to soldering heat

12

Moisture resistance

Subgroup 4 6/

6

1

Marking legibility (laser marking only) 5/

Resistance to solvents (ink marking only) 5/

Subgroup 5

12 minimum per

Life (at elevated ambient temperature)

7/

group

(see 4.6.1.1.1)

1/ A sample unit having one or more defects shall be considered a single defective.

2/ If the manufacturer can demonstrate that this test has been performed five consecutive times with zero

failures, the frequency of this test, with the approval of the qualifying activity, can be performed on an

annual basis. If the design, material, construction, or processing of the part is changed or, if there are any

quality problems or failures, the qualifying activity may require resumption of the original test frequency.

3/ Subgroup 2 and subgroup 3 shall be checked during alternate bimonthly periods.

4/ Subgroup 2 or subgroup 3 tests may be performed on sample units that have been subjected to and have

passed the subgroup 1 tests, when these sampling periods coincide.

5/ If the manufacturer can demonstrate that this test has been performed five consecutive times with zero

failures, this test, with the approval of the qualifying activity, can be deleted. The manufacturer, however,

shall perform this test every three years after the deletion as part of long term design verification. If the

design, material, construction, or processing of the part is changed or, if there are any quality problems, the

qualifying activity may require resumption of the specified testing. Deletion of testing does not relieve the

manufacturer from meeting the test requirement in case of dispute.

6/ Applicable to active for new design styles (ER and non-ER) only.

7/ For non-ER, one defective is permitted. For ER, the number of allowable defectives may vary with the

failure rate level of the part being tested.

4.7 Methods of examination and test.

4.7.1 Visual and mechanical examination. Capacitors shall be examined to verify that the materials, design,

construction, physical dimensions, marking, and workmanship are in accordance with the applicable requirements.

4.7.2 Thermal shock and voltage conditioning (ER parts only) (see 3.6). Capacitors shall be subjected to the tests

18

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business