MIL-PRF-14409J

4.3.4 Verification of qualification. Every 12 months the manufacturer shall provide verification of qualification to

the qualifying activity. Continuation of qualification shall be based on meeting the following requirements.

a. Group A inspection.

b. Group B inspection.

c. Periodic group C inspection.

In the event that there is no production of a single device during a reporting period and the manufacturer is listed for

more than one style on the QPL, the manufacturer shall certify that they retain the capabilities and facilities necessary

to produce that product. If during three consecutive reporting periods there has been no production of a given style,

the manufacturer may be required, at the discretion of the qualifying activity, to submit a representative product of

that style to testing.

4.4 Conformance inspection.

4.4.1 Inspection of product for delivery. Inspection of product for delivery shall consist of groups A and B

inspection. Except as specified in 4.4.2.1.4, delivery of products that have passed the groups A and B inspection

shall not be delayed pending the results of group C inspection.

4.4.1.1 Inspection lot. An inspection lot, shall consist of all capacitors of the same style and characteristic,

produced under essentially the same conditions, and offered for inspection at one time, except combinations of the

styles represented by individual groups of table A-I may be grouped and considered an inspection lot provided the

capacitors are of the same characteristic, produced under essentially the same conditions, and offered for inspection

at one time. This definition shall apply to group A and group B tests only.

4.4.1.2 Group A inspection. Group A inspection shall consist of the examinations and tests specified in table III,

in the order shown.

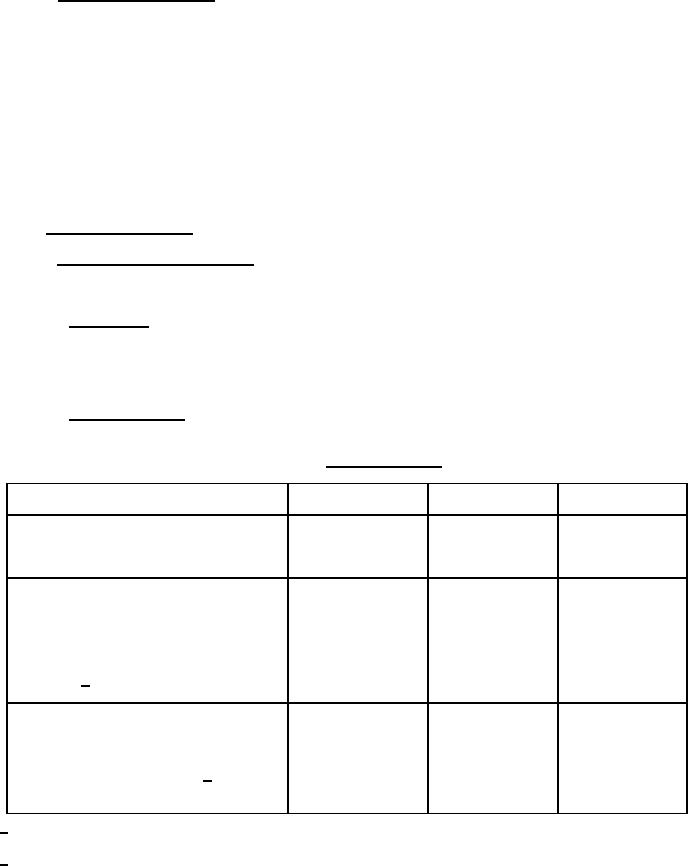

TABLE III. Group A inspection.

Requirement

Test

Sampling

Inspection

paragraph

paragraph

procedure

Thermal shock (styles PC21, PC22,

PC23, PC24, PC26, PC27, PC28,

100 percent

PC29, PC30, PC32, and PC34)

inspection

Visual and mechanical examination:

Material

4.5.2

Body dimensions

13 samples

Design and construction (other than body

0 failures

dimensions)

Marking 1/

Workmanship

Capacitance

Change of capacitance

Insulation resistance (at 25°C)

13 samples

0 failures

Dielectric withstanding voltage 2/

Quality factor (Q)

Driving torque (room ambient temperature)

1/ Marking defects are based on visual examination only, and will be charged only for illegible, incomplete, or

incorrect marking. Any subsequent electrical defects will not be used as a basis for determining marking defects.

2/ Dielectric withstanding voltage will be during capacitor cycle.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business