MIL-PRF-14409J

4.5.8.1.2 Conformance inspection.

4.5.8.1.2.1 Group A inspection. The test specified in 4.5.8.1 shall be performed at room ambient temperature.

4.5.8.1.2.2 Group C inspection. The test specified in 4.5.8.1 shall be performed at -55°C +0°C, -3°C, and at the

applicable high test temperature, +5°C, -0°C.

4.5.8.2 Torque, bushing strength (panel mounts only) (see 3.11.2). The capacitor shall be mounted through the

suggested hole (see 3.1) in a metal panel of .125 inch (3.18 mm) maximum thickness, while the applicable torque

specified in table VI is applied to the nut. The torque shall be applied in the direction which will tighten the nut and

shall be held at its specified value for a period of not less than 3 seconds. It shall be applied repeatedly to the nut

until a total of five twists have been applied. After the test, the capacitor shall be visually examined for evidence of

bushing breakage, thread stripping, or other visible mechanical damage.

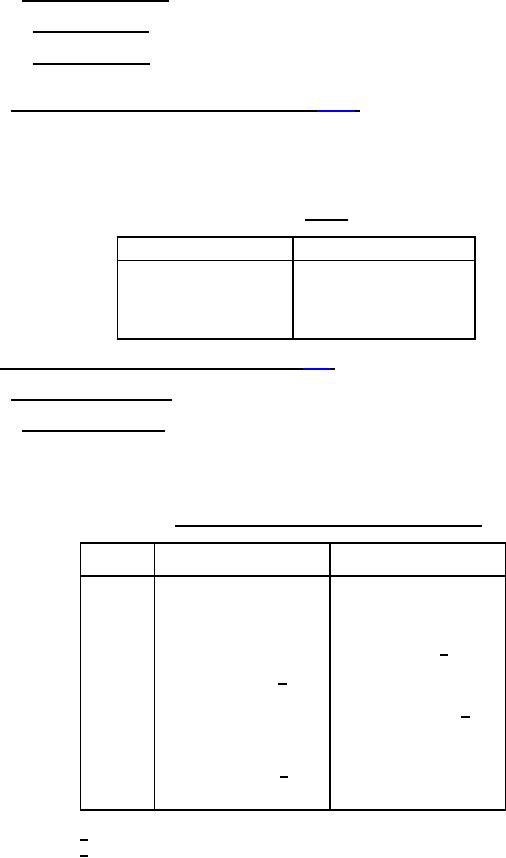

TABLE VI. Torque.

Torque ±0.1 (inch-pounds)

Bushing size

.120

1.2

.190-64

3.0

.234

5.0

.190-32

6.0

.250

8.0

4.5.9 Temperature coefficient and capacitance drift (see 3.12).

4.5.9.1 For qualification inspection.

4.5.9.1.1 Temperature coefficient. With capacitors set at approximately 75 percent of maximum rated

capacitance, capacitance measurements shall be made at a frequency of 1 MHz ±100 kHz and at the temperatures

specified in table VII. Each measurement shall be made after thermal stability has been reached. (Thermal stability

has been reached when no further change in capacitance is obtained between two successive measurements taken

at 5 minute intervals.) Accuracy of measurements shall be within ±0.01 pF.

TABLE VII. Temperature coefficient and capacitance-drift cycle.

Qualification inspection

Conformance inspection

Steps

temperature (°C)

temperature (°C)

25 ±2

a

25 +2, -2

b

-55 +0, -2

-55 +0, -2

25 ±2 1/

c

-10 +2, -2

25 +2, -2 1/

d

125 +2, -0

85 +2, -0

e

150 +2, -0 2/

25 ±2

125 +2, -0

f

150 +2, -0 2/

g

h

25 +2, -2

1/ This temperature shall be considered as the reference temperature.

2/ For characteristic Q only.

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business