MIL-PRF-14409J

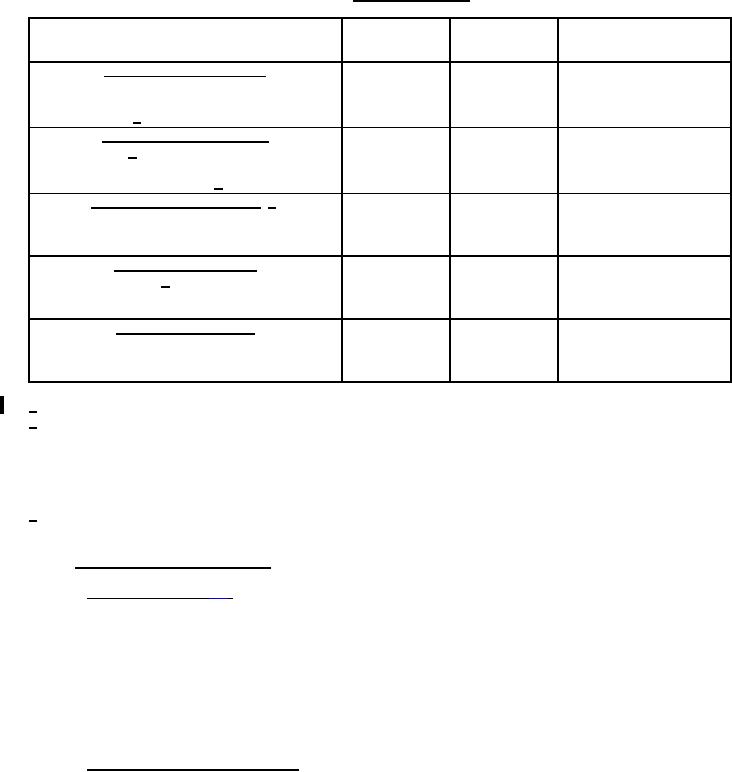

TABLE V. Group C inspection.

Requirement

Test method

Test

Sampling procedure

paragraph

paragraph

Subgroup I (semiannually)

Insulation resistance (at high temperature)

12 samples per

Temperature coefficient and capacitance drift

characteristic

Thermal shock 1/

1 failure

Subgroup II (semiannually)

Driving torque 2/

12 samples per

Terminal strength

characteristic

Resistance to soldering heat 1/

1 failure

Subgroup III (semiannually) 3/

Immersion (sealed units only)

12 samples per

Salt atmosphere (corrosion)

characteristic

1 failure

Subgroup IV (annually)

Moisture resistance 1/

12 samples per

characteristic

1 failure

Subgroup V (annually)

Shock (specified pulse)

12 samples per

Vibration, high frequency

characteristic

1 failure

1/ Capacitance, insulation resistance, and quality factor will follow last test of subgroups I, II, and IV.

2/ If the manufacturer can demonstrate that this test has been performed five consecutive times with zero failures,

this test, with the approval of the qualifying activity, can be deleted. The manufacturer, however, shall perform

this test every 3 years after the deletion as part of long term design verification. If the design, material,

construction processing of the part is changed, or if there are any quality problems, the qualifying activity may

require resumption of the specified testing. Deletion of testing does not relieve the manufacturer from meeting the

test requirements in case of dispute.

3/ Electrical tests are not required on unsealed units.

4.5 Methods of examination and test.

4.5.1 Thermal shock (see 3.5). Capacitors shall be tested in accordance with method 107 of MIL-STD-202. The

following details shall apply:

a. Test condition: B (styles PC26 (characteristic T), PC32, and PC34) or A (all other styles), except that in

step 3, capacitors shall be tested at the high test temperature, ±5°C (see 3.1).

b. Measurements before and after cycling: Not applicable.

After the test, capacitors shall be visually examined for evidence of fracture, corrosion, or loosening of mechanical

connections.

4.5.2 Visual and mechanical examination. Capacitors shall be examined to verify that the material, design,

construction, physical dimensions, marking, and workmanship are in accordance with the applicable requirements

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business