MIL-PRF-11693E

3.5 Interface and physical dimension requirements. Capacitors shall meet the interface and physical dimensions

specified (see 3.1).

3.5.1 Case. Each capacitor shall be enclosed in a hermetically sealed metal case that will prevent leakage of the

impregnant or filling compound, and will protect the capacitor element from moisture and mechanical damage under

all test conditions specified herein.

3.5.2 Finish. All exposed metal surfaces shall be suitably protected against corrosion by plating, or other means

(see 3.15). The resultant finish shall form a good electrical conductor and shall be free from defects that may affect

its protective value.

3.5.2.1 Pure tin. The use of pure tin, as an underplate or final finish, is prohibited both internally or externally,

including nuts and washers. Tin content of capacitor components and solder shall not exceed 97 percent, by mass.

Tin shall be alloyed with a minimum of 3 percent lead, by mass (see 6.9).

Lead-free, tin alloy high temperature solders may be used where high temperature solder is necessary with the

approval of the qualifying activity. The tin content of lead-free high temperature solders shall not exceed 97 percent,

by mass.

3.5.3 Threaded parts. All threaded parts shall be as specified (see 3.1) and in accordance with FED-STD-H28.

Aluminum nuts shall not be used.

3.5.3.1 Engagement of threaded parts. All threaded parts shall engage by at least two full threads.

3.6 Seal. When capacitors are tested as specified in 4.7.2, there shall be no continuous visible stream of bubbles

or other evidence of leakage.

3.7 Terminal strength. When capacitors are tested as specified in 4.7.3, no part of the terminal shall loosen or

rupture, and there shall be no other damage. Stud-type terminals shall exhibit no perceptible movement relative to

the case, under the applied torque.

3.8 Dielectric withstanding voltage. When capacitors are tested as specified in 4.7.4, there shall be no visible

damage, flashover, breakdown, open-circuiting or short-circuiting.

3.9 Insulation resistance. When measured as specified in 4.7.5, the insulation resistance, shall be not less than

the applicable value specified in table IV and shown on figure 1. For measurements made at temperatures between

+20° and +35°C, the applicable correction factor specified in table V shall be applied.

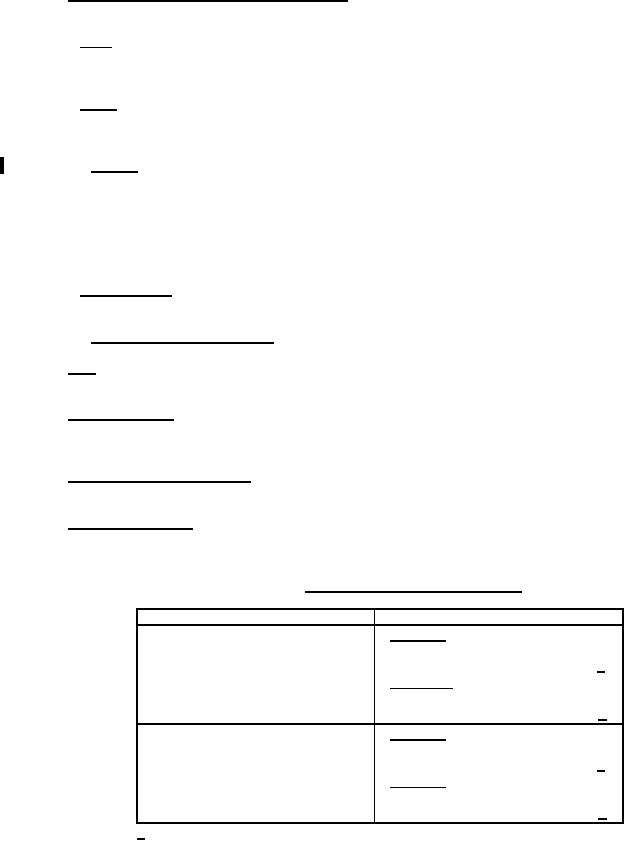

TABLE IV. Insulation resistance measurements.

Capacitance rating

Minimum insulation resistance

At +25°C

Characteristic K

0 to 0.33 microfarads

A 18,000 megohms

Greater than 0.33 microfarads

6,000 megohm-microfarads 1/

At +125°C

0 to 0.067 microfarads

150 megohms

Greater than 0.067 microfarads

10 megohm-microfarads 1/

At +25°C

Characteristic E

0 to 0.33 microfarads

6,000 megohms

Greater than 0.33 microfarads

2,000 megohm-microfarads 1/

At +85°C

0 to 0.033 microfarads

600 megohms

Greater than 0.033 microfarads

20 megohm-microfarads 1/

1/ Product obtained by multiplying the capacitance in microfarads (µF) by the

insulation resistance.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business