MIL-PRF-11693E

4.4.2 Inspection routine. The sample shall be subjected to the inspections specified in table VI, in the order

shown. All sample units shall be subjected to the examinations of group I (two sample units shall be subjected to the

visual and mechanical examination (internal) and the remaining sample units shall be subjected to the subsequent

examinations of group I. The specimens will then be divided into the remaining groups specified in table VI, and

subjected to the tests for their particular group.

4.4.3 Failures. Failures in excess of those allowed in table VI shall be cause for refusal to grant qualification

approval.

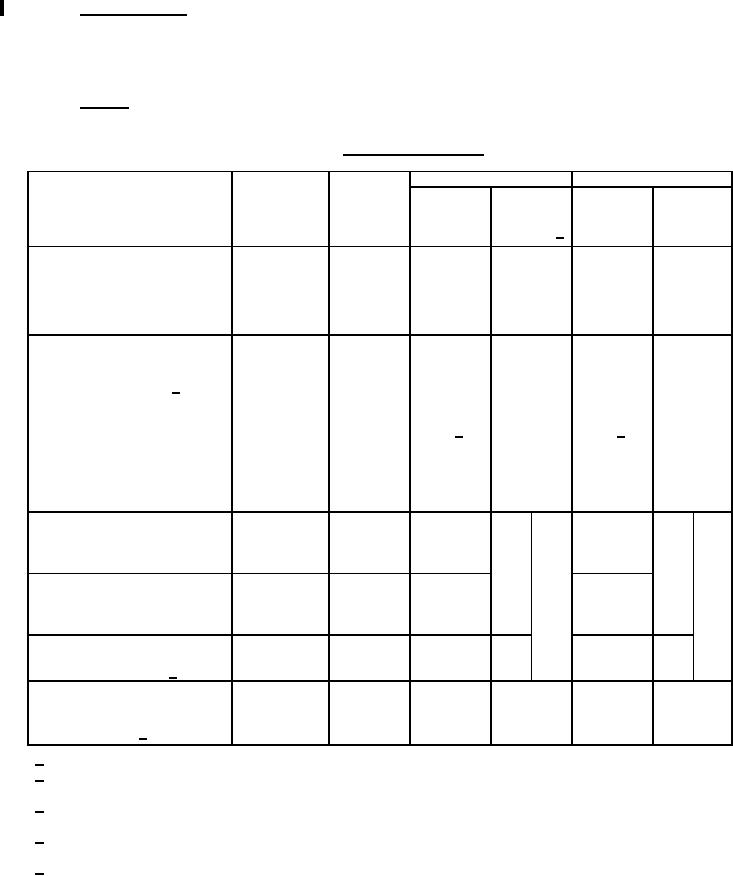

TABLE VI. Qualification Inspection.

NON-ER

ER

Number of

Number of

Test method

Requirement

Number of

Number of

Inspection

sample units

sample units

paragraph

paragraph

defects

defects

to be

to be

permitted 1/

permitted

inspected

inspected

Group I

Visual and mechanical

examination (internal):

Material and workmanship

2

0

2

0

3.5.3.1, and

Visual and mechanical

examination (external):

Physical dimensions, marking,

and workmanship 2/

Seal

Terminal strength

29 3/

57 3/

Dielectric withstanding voltage

1

1

Insulation resistance

Capacitance

Dissipation factor

Insertion loss

DC resistance

Group II

Resistance to soldering heat

Salt atmosphere (corrosion)

6

6

Thermal shock and immersion

1

1

Group III

Shock (specified pulse)

1

1

Vibration, high frequency

6

6

Moisture resistance

Group IV

Solderability

4

1

4

1

Resistance to solvents 5/

Group V

Low temperature and capacitance

change at reduced temperature

12

1

40

1

Life (accelerated) 4/

1/ A specimen having one or more defects will be considered as a single defective.

2/ Marking will be considered as a defect only if it becomes illegible as a result of any of the tests of the

specification.

3/ One additional specimen is included in each sample of 31 or 59 specimens as applicable to permit substitution

for the allowable defective in group I.

4/ The decision as to whether or not the NON-ER product is to be included on the qualified products list shall be

made at the end of the 240 hour life test and at the conclusion of the 2,000-hour life test for the ER parts.

5/ Two capacitors with sleeves and two unsleeved.

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business