MIL-C-62F

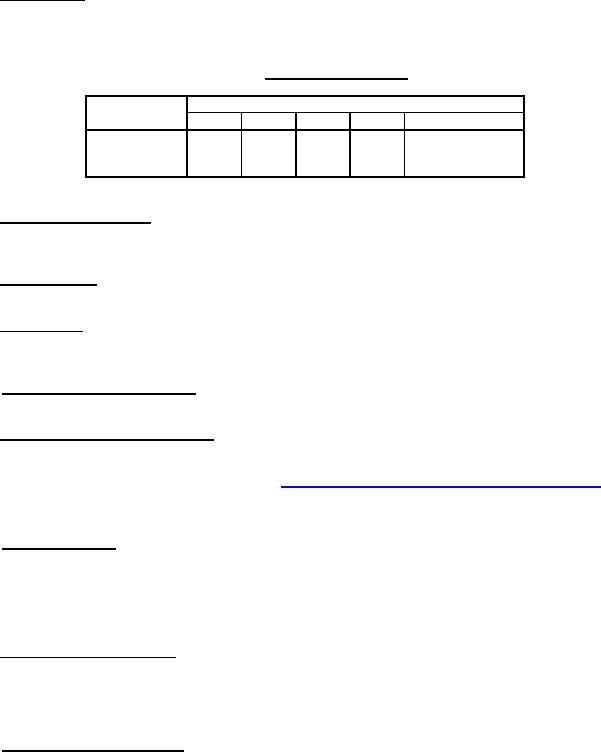

6.12 Ripple current. To avoid overheating and shortened life, the maximum rms ripple current through the

capacitor should not exceed the value determined. The formulas (see 3.1) for calculating the ripple current are based

on operation at 120 Hz and 85C. For other frequencies or temperatures the calculated value should be multiplied by

the applicable factor from table X.

TABLE X. Ripple current multiplier.

Frequency

Multiplier

+85C

+65C

+55C +45C

+40C and below

60 Hz

0.8

1.2

1.6

2.2

3.0

120 Hz

1.0

1.5

2.0

2.8

3.0

Above 120 Hz

1.1

1.7

2.2

3.0

3.0

6.13 Standard capacitor types. Equipment designers should refer to MIL-HDBK-198 "Capacitors, Selection and

Use of", for standard capacitor types and selected values chosen from this specification. MIL-HDBK-198 provides a

selection of standard capacitors for new equipment design.

6.14 Application data. Capacitor styles CE63 and CE64 are retained for replacement and maintenance purposes

only. For new design, use styles CE11 or CE13.

6.15 Supersession. Minor changes made in this revision, in order to incorporate decade capacitance values,

standardize case dimensions, and standards DF or impedance limits, will not require assignation of new stock

numbers.

6.16 Part or Identifying Number (PIN). This specification requires a PIN that describes codification and/or

6.17 Environmentally preferable material. Environmentally preferable materials should be used to the maximum

*

extent possible to meet the requirements of this specification. As of the dating of this document, the U.S.

Environmental Protection Agency (EPA) is focusing efforts on reducing 31 priority chemicals. The list of chemicals

and additional information is available on their website https://www.epa.gov/osw/hazard/wastemin/priority.htm. Use of

these materials should be minimized or eliminated unless needed to meet the requirements specified herein (see

Section 3).

6.18 Tin whisker growth. The use of alloys with tin content greater than 97 percent by mass, may exhibit tin

*

whisker growth problems after manufacturer. Tin whiskers may occur anytime from a day to years after manufacturer

and can develop under typical operating conditions, on products that use such materials. Conformal coatings applied

over top of a whisker-prone surface will not prevent the formation of tin whiskers. Alloys of 3 percent lead, by mass,

have shown to inhibit the growth of tin whiskers. For additional information on this matter, refer to ASTM-B545

(Standard Specification for Electrodeposited Coatings of Tin).

6.19 Changes from previous issue. The margins of this specification are marked with asterisks to indicate where

changes from the previous issue were made. This was done as a convenience only and the Government assumes no

liability whatsoever for any inaccuracies in these notations. Bidders and contractors are cautioned to evaluate the

requirements of this document based on the entire content irrespective of the marginal notations and relationship to

the last previous issue.

6.20 Subject term (key word) listing.

Capacitance

Dissipation factor

Insulation resistance

20

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business