MIL-C-62F

4.4.1.2 Group A inspection. Group A inspection shall consist of the examination and tests specified in table V, and

shall be made on the same set of sample units, in the order shown.

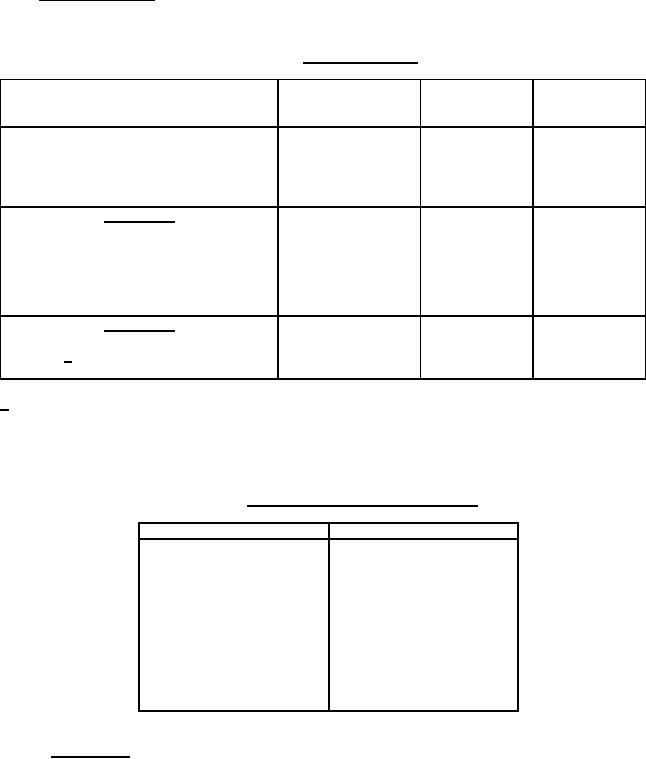

TABLE V. Group A inspection.

Inspection

Requirement

Test

Sampling

paragraph

Method

procedure

paragraph

Subgroup 1

3.6

4.5.3

See table VI

DC leakage

3.7

4.5.4

Capacitance

3.8

4.5.5

Dissipation factor

Subgroup 2

Visual and mechanical examination:

5 samples

Material

3.3 and 3.31

4.5.1

0 failures

Physical dimentions

3.4

Design and construction (other than

3.4.1 to 3.4.3

physical dimentions

Subgroup 3

5 samples

Marking 1/

3.22 and 3.22.1

4.5.1

0 failures

Workmanship

3.23

1/ Marking defects are based on visual examination only and shall be charged only for illegible,

incomplete, or incorrect marking. Any subsequent electrical defects shall not be used

as a basis for determining marking defects.

TABLE VI. Sampling plans for Group A inspection.

Lot size

Sample size

1

13

100%

14

150

13

151

280

20

281

500

29

501 1,200

34

1,201 3,200

42

3,201 10,000

50

10,001 35,000

60

35,001 150,000

74

150,001 500,000

90

500,001 - Up

102

4.4.1.2.2 Rejected lots. If an inspection lot is rejected, the supplier may withdraw the lot, rework it to correct the

defects, or screen out the defective units, as applicable, and re-inspect. Such lots shall be separate from new lots,

and shall be clearly identified as re-inspected lots.

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business