MIL-PRF-83500A

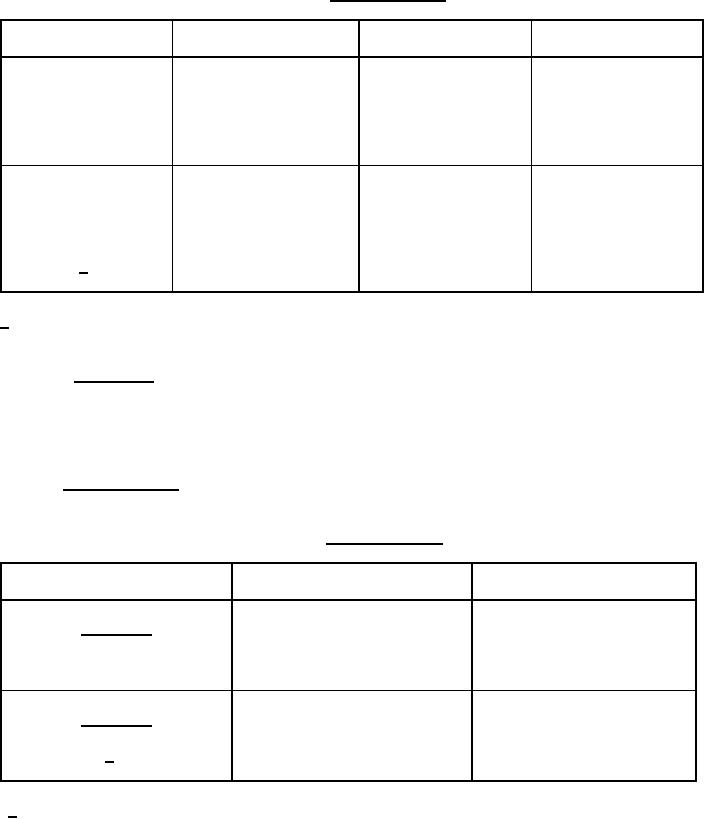

TABLE II. Group A inspection.

Requirement

Test

Sampling

Examination or test

paragraph

paragraph

Procedure

Burn-in

3.5

4.6.2

100 percent inspection

DC leakage

3.6

4.6.3

Capacitance

3.7

4.6.4

Dissipation factor

3.8

4.6.5

Visual and mechanical

13 samples

Examination (external)

3.1 and 3.3

4.6.1

0 failures

Materials

3.1

4.6.1

Physical dimensions

Marking 1/

3.29

4.6.1

Workmanship

3.31

4.6.1

1/ Marking defects shall be based on visual inspection only. Any subsequent electrical defects shall not be used as

a basis for determining marking defects.

4.5.1.2.1 Rejected lots. If an inspection lot is rejected, the supplier may rework it to correct the defects, or screen

out the defective units, and resubmit for reinspection. A new sample of parts shall be randomly selected in

accordance with Table II. Such lots shall be separate from new lots, and shall be clearly identified as reinspected

lots. If one or more defects are found in this second sample, the lot shall be rejected and shall not be supplied to this

specification.

4.5.1.3 Group B inspection. Group B inspection shall consist of the tests specified in table III, in the order shown,

and shall be performed on sample units which have been subjected to and have passed group A inspection.

TABLE III. Group B inspection.

Requirement

Test

Test

paragraph

paragraph

Subgroup 1

Stability at low and high

temperatures - - - - - - - - - - - - -

3.19

4.6.16

Subgroup 2

Thermal shock 1/ - - - - - - - - - - -

3.11

4.6.8

Life at 85°C (240-hour) - - - - - - -

3.22.2

4.6.19.2

1/ Twenty-five cycles. No failures allowed.

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business