MIL-PRF-83500A

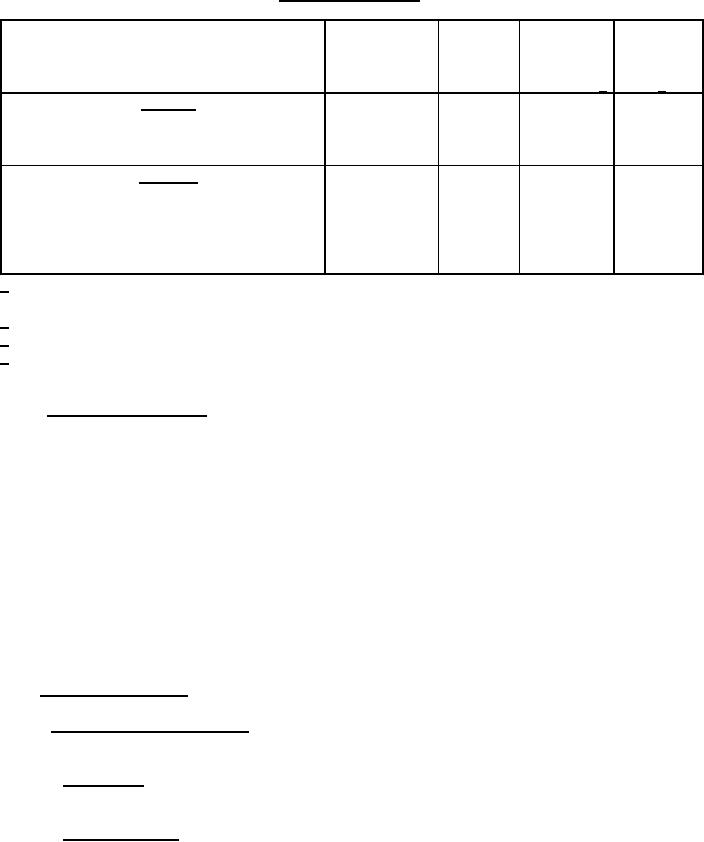

TABLE I. Qualification inspection - Continued.

Number of

Number of

Examination or test

Requirement

Test

sample

failures

paragraph

paragraph

units to be

permitted

inspected 1/

2/

Group VI

Vacuum life at 125°C - - - - - - - - - - - - - - - - - - - - -

3.24

4.6.21

27

1

AC ripple life at 125°C - - - - - - - - - - - - - - - - - - - -

3.25

4.6.22

Group VII

Fungus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

3.26

4.6.23

Resistance to solvents - - - - - - - - - - - - - - - - - - -

3.27

4.6.24

6

1

Resistance to soldering heat (capacitors

With terminal tabs only) - - - - - - - - - - - - - - - - -

3.28

4.6.25

1/ One additional sample unit is included in each sample of 72 units to permit substitution for the failure allowed in

group I.

2/ A sample unit having one or more defects shall be considered as a single failure.

3/ Nondestructive inspection and tests.

4/ Marking defects are based on visual examination only and shall be charged only for illegible, incomplete, or

incorrect marking.

4.4 Verification of qualification. Every 12 months, the manufacturer shall verify the retention of qualification to

the qualifying activity. In addition, the manufacturer shall immediately notify the qualifying activity whenever Group C

inspection results indicate failure of the qualified product to meet the requirements of the specification. Verification of

qualification shall be based on meeting the following:

a.

The capacitor design has not been modified.

b.

Lot rejection for group A inspection does not exceed the group A sampling plan.

d.

The requirements for group C inspection are met.

In the event that there is no production of a single style device during a reporting period and the manufacturer is

listed for more than one style on the QPL, the manufacturer shall certify that they retain the capabilities and facilities

necessary to produce that product. If during three consecutive reporting periods there has been no production of a

given style the manufacturer may be required, at the discretion of the qualifying activity, to submit a newly-produced

(not from stock) representative product of that style to testing.

4.5 Conformance inspection.

4.5.1 Inspection of product for delivery. Inspection of product for delivery shall consist of groups A and B

inspections.

4.5.1.1 Inspection lot. An inspection lot shall consist of all capacitors, from a production line or lines, produced

under essentially the same conditions and offered for inspection in a single work-week.

4.5.1.2 Group A inspection. Group A inspection shall consist of the examination and tests specified in table II, in

the order shown.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business