MIL-PRF-19978/13C

REQUIREMENTS:

Design and construction:

Case material - Nonmagnetic (end seal may be of magnetic material).

Terminals - Axial-wire lead (see figure 1).

3

Rated voltage - See table II.

Rated temperature - -65° to +85°C.

Capacitance (Cap.) (nom) - See table II.

Capacitance tolerance - See table II.

Dissipation factor (DF) (max) - 0.6 percent.

Failure rate level - In accordance with MIL-PRF-19978.

Reliability - In accordance with MIL-PRF-19978.

Burn-in: In accordance with MIL-PRF-19978.

Radiographic inspection: In accordance with MIL-PRF-19978.

Seal: Method 112 of MIL-STD-202, test condition letter A or test condition letter B with mineral oil.

Dielectric withstanding voltage (DWV):

Sleeving - In accordance with MIL-PRF-19978.

Barometric pressure: In accordance with MIL-PRF-19978.

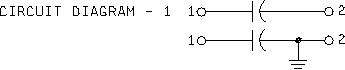

Test points:

Circuit diagram 1 - Between terminals and case.

Circuit diagram 3 - Between ungrounded terminal and case.

Insulation resistance (IR):

Sleeving - In accordance with MIL-PRF-19978.

Terminal to terminal - See table I.

Vibration, high frequency: Method 204 of MIL-STD-202, test condition B, with the following exception:

Direction and duration of motion - 4 hours in each of two mutually perpendicular directions (total of 8 hours), one

parallel and the other perpendicular to the cylindrical axis.

2