MIL-C-11272E

4.5.2.1.6 Noncompliance. If a sample fails to pass group B inspection, the supplier shall take corrective action on

the materials or processes, or both, as warranted, and on all units of product that can be corrected, and that were

manufactured under essentially the same conditions, with essentially the same materials, processes, etc., and which

are considered subject to the same failure. Acceptance of the product shall be discontinued until corrective action,

acceptable to the Government, has been taken. After the corrective action has been taken, group B inspection shall

be repeated on additional sample units (all inspection, or the inspection that the original sample failed, at the option

of the Government). Group A inspection may be re-instituted; however, final acceptance shall be withheld until the

group B re-inspection has shown that the corrective action was successful. In the event of failure after re-inspection,

information concerning the failure and corrective action taken shall be furnished to the cognizant inspection activity

and the qualifying activity.

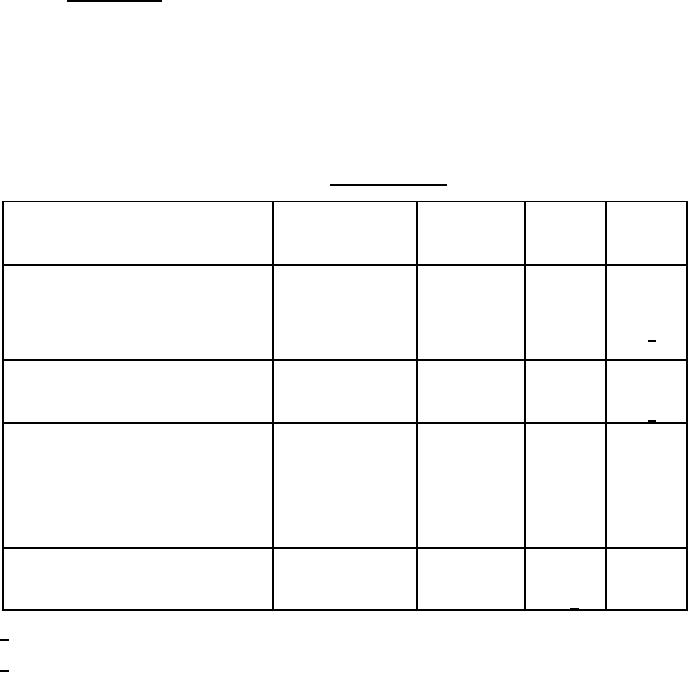

TABLE VIII. Group B inspection.

Number of

Number of

defectives

sample

Test method

Test

Requirement

permitted

units to be

paragraph

paragraph

inspected

Subgroup I

(Every 4 months)

Shock (specified pulse)

1 2/

12

Vibration, high frequency

Thermal shock and immersion

Subgroup II

(Every 4 months)

1 2/

12

Moisture resistance

Subgroup III

(Every 4 months)

Solderability

1

12

Terminal strength

Temperature coefficient and

4.6.15.2 to

capacitance drift

incl

Subgroup IV

(Every 6 months)

Life (continuation test)

24 1/

1

1/

Sample units to be inspected shall be selected from sample units that have been subjected to the 250-hour

performance-check test.

2/

If the failures exceed the total number permitted by 1, the inspection shall be rerun with the same sample size

with zero failures permitted.

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business