MIL-PRF-20M

APPENDIX A

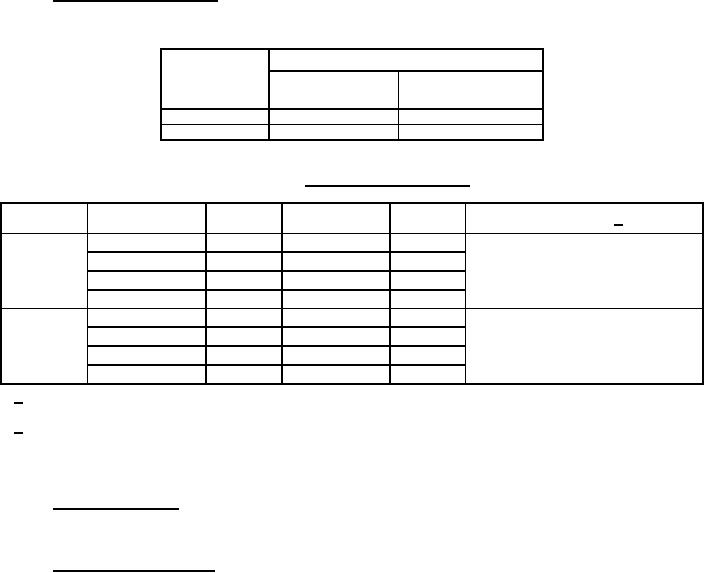

A.4.2 Combined style submission. Combined style submission shall be restricted as shown in table A-I.

Qualification of ER styles with standoffs will be extended to similar ER and non-ER styles without standoffs as

follows:

Will extend qualification to

Qualification to

ER without

non-ER without

ER standoff

standoff

standoff

CCR05

CCR05

CC05

CCR06

CCR06

CC06

TABLE A-I. Combined style submission.

Qualification

Number of

Number of

ER PIN

Non-ER PIN

Will qualify 1/

group

samples

samples

CCR05, 06, 07, 08, 09,

CCR05CG331GM

25

CC05CG331GM

16

CC05, 06, 07, 08, 09 in

CCR05CG332GM

25

CC05CG332GM

16

CG and CH characteristics;

I

CCR08CG472GM

25

CC08CG472GM

19

B, C, D, F, G, J, K cap. tolerance;

CCR08CG683GM

25

CC08CG683GM

19

200, 100, and 50 volts; FRL M.

CCR75, 76, 77, 78, 79,

CCR75CG750GM

25

CC75CG750GM

16

CC75, 76, 77, 78, 79 in

CCR75CG681GM

25

CC75CG681GM

16

II

CG and CH characteristics;

CCR79CG103GM

25

CC79CG103GM

19

B, C, D, F, G, J, K cap. tolerance;

CCR79CG823GM

25

CC79CG823GM

19

200, 100, and 50 volts; FRL M.

1/ ER style qualification will qualify equivalent non-ER style. Non-ER style qualification will qualify non-ER

style only.

2/ For qualification of style CCR05 with standoffs, see A.4.2.

A.5. SOLDER DIP (RETINNING) LEADS

A.5.1 Solder dip (retinning). The manufacturer may solder dip/retin the leads of capacitors supplied to this

specification, provided the solder dip process (see A.5.2) or an equivalent process has been approved by the

qualifying activity.

A.5.2 Qualifying activity approval. Approval of the solder dip process will be based on one of the following options:

a. When the original lead finish qualified was hot solder dip lead finish 52 in accordance with MIL-STD-1276

(NOTE: The 200 microinch maximum thickness is not applicable), the manufacturer shall use the same solder

dip process for retinning as was used in the original manufacture of the capacitor.

b. When the lead originally qualified was not hot solder dip lead finish 52 of MIL-STD-1276 as prescribed in

A.5.2a, approval for the process to be used for solder dip shall be based on the following procedure:

(1) Thirty samples of any capacitance value for each style and lead finish shall be subjected to the

manufacturer's solder dip process. The capacitors shall then be subjected to all group A, subgroup 1

post-electrical tests, with no defects allowed.

(2) Ten of the thirty samples shall then be subjected to the solderability test, with no defects allowed.

(3) The remaining 20 samples shall be subjected to the resistance to soldering heat test, followed by the

moisture resistance test, with no defects allowed.

33

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business