MIL-PRF-19978K

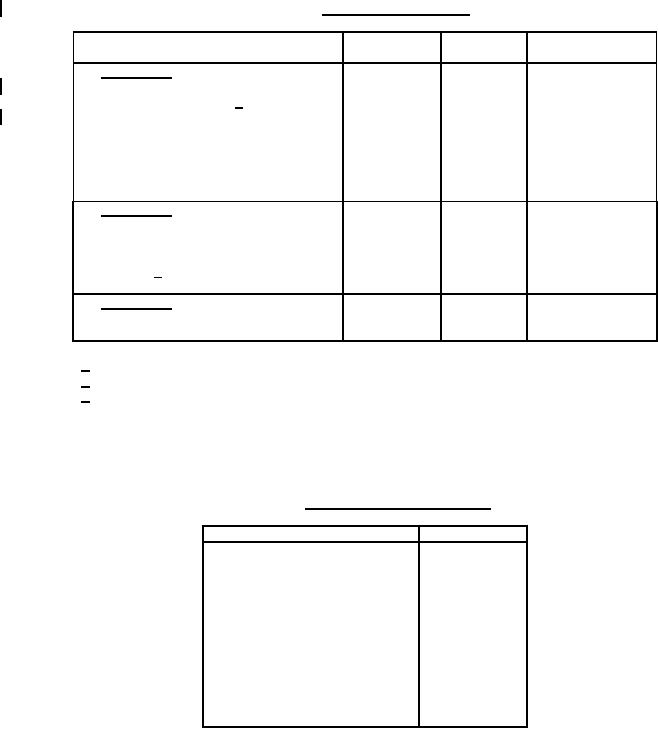

TABLE X. Group A inspection (ER).

Requirement

Test method

Sampling

Inspection

paragraph

paragraph

procedure

Subgroup 1

Thermal shock

Radiographic inspection 1/

Burn in

Seal

100% inspection

Dielectric withstanding voltage

Insulation resistance

Capacitance

Dissipation factor

Subgroup 2

Visual and mechanical examination

(external):

See table XI

Physical dimensions

Marking 2/

inclusive

Workmanship

Subgroup 3 3/

5 samples

Solderability (wire lead styles only)

0 failures

1/ Radiographic not applicable to FRL M.

2/ Marking defects are based on visual examination only.

3/ The manufacturer may request the deletion of the subgroup 3 solderability test, provided

an in-line or process control system for assessing and assuring the solderability of leads

can be validated and approved by the qualifying activity. Deletion of the test does not

relieve the manufacturer from meeting this test requirement in case of dispute. If the

design, material, construction, or processing of the part is changed or if there are any

quality problems, the qualifying activity may require resumption of the test.

TABLE XI. Sampling plans for subgroup 2.

Lot size

Sample size

1

-

13

100%

14

-

125

13

126

-

150

13

151

-

280

20

281

-

500

29

501

-

1,200

34

1,201

-

3,200

42

3,201

-

10,000

50

10,001

-

35,000

60

35,001

- 150,000

74

150,001

- 500,000

90

500,001

-

Up

102

15

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business