MIL-C-39022/9D

REQUIREMENTS:

Design and construction:

Dimensions and configuration: See figure 1 and table I.

Case material: Nonmagnetic. Seal headers may be magnetic.

Sleeves: Heat shrink only.

Leads:

500 inch (12.70 mm) and smaller case diameters: Solder-coated copper clad steel. Type N2 of MIL-

STD-1276 may be furnished when specified in the contract or purchase order (see MIL-PRF-39022

ordering data).

.562 inch (14.27 mm) and larger case diameters: Type C of MIL-STD-1276.

Capacitance value: See table I.

Capacitance tolerance: See table I.

Rated voltage: DC and ac (see table I).

Operating temperature range: -55°C to +100°C; linearly derate to 50 percent of rated voltage for +125°C

operating.

Failure rate level: M (1.0 percent), P (0.1 percent), R (0.01 percent), and S (0.001 percent) (established at dc

rated voltage at +100°C.

Flash point of impregnant: Not applicable.

Radiographic inspection (X-ray): Not applicable.

Thermal shock: Method 107 of MIL-STD-202, condition B.

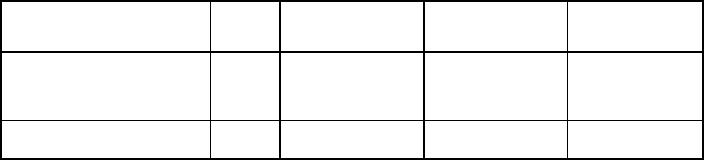

Seal: Method 112 of MIL-STD-202, test condition C, procedure IIIA; no evidence of leakage with the exception

of the following:

R1

Exposure time

Maximum dwell

2

Styles

Reject limit

lbf/in

hours

hours

3

(atm cm /s)

CHR01A, CHR01B, CHR01D,

-6

45 ± 5

1 +1-0

1

1 x 10

CHR01E, CHR01G, CHR01H,

CHR01K, CHR01L, CHR01N,

AND CHR01P

CHR01C, CHR01F, CHR01J,

45 ± 5

-5

1 +1-0

1

1 x 10

CHR01M, AND CHR01R

2