MIL-PRF-81F

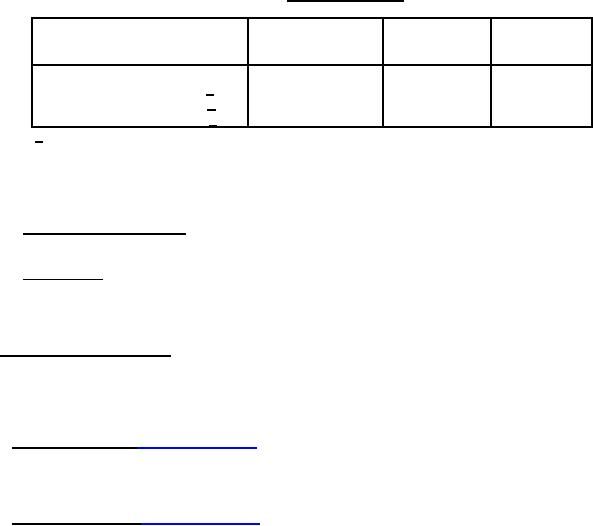

TABLE IV. Group B inspection.

Inspection

Requirement

Method

Sampling

paragraph

paragraph

procedure

5 samples

1/

Terminal strength

0 failures

Torque

1/

Temperature coefficient

1/

1/ If the manufacturer can demonstrate that this test has been performed five consecutive

times with zero failures, the frequency of this test, with the approval of the qualifying activity,

can be performed on an annual basis. If the design, material, construction, or processing of

the part has changed or if there are any quality problems or failures, the qualifying activity

may require resumption of the original test frequency.

4.4.3.2 Disposition of sample units. Sample units which have been subjected to group B inspection shall not be

delivered on the contract or order.

4.4.3.3 Rejected lots. If an inspection lot is rejected, the supplier may withdraw the lot, rework it to correct the

defects, or screen out the defectives, as applicable, and reinspect. Such lots shall be kept separate from new lots

and shall be clearly identified as re-inspected lots. Failure of a resubmitted lot due entirely to failure to pass the tests

which caused a previous rejection shall be cause for final rejection.

4.5 Periodic Group C inspection. Group C inspection shall consist of the tests specified in table V, in the order

shown. Sample units shall be taken at random from capacitors currently in production. The number of sample units

to be inspected shall be as specified in table V. Separate samples of the amount required by table V shall be used

for each sampling period and each subgroup listed. Failures in excess of those allowed in table V shall constitute

failure. Delivery of units is not to be delayed pending results of group C testing.

4.5.1 Sampling procedure Table V subgroup 1. At the discretion of the procuring activity, but not in excess of

once every 2 months, a sample consisting of 12 sample units of each style and characteristic shall be taken at

random from capacitors currently in production. These specimens shall have passed all group A tests. No more than

one failure is allowed.

4.5.2 Sampling procedure, Table V subgroup 2. At the discretion of the procuring activity, but not in excess of

once every 12 months, a sample consisting of 18 sample units of each style and characteristic shall be taken at

random from capacitors currently in production. These specimens shall have passed all group A tests. No more than

one failure is allowed.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business