MIL-PRF-81F

4.6.3 Barometric pressure (reduced, qualification only) (see 3.6). Capacitors shall be tested in accordance with

method 105 of MIL-STD-202. The following details shall apply.

a.

Mounting: Normal mounting means.

Test condition: D (100,000 feet), and when applicable (see 3.1), condition B (50,000 feet).

b.

Tests during subjection to reduced pressure: Unless otherwise specified (see 3.1), a potential equal to the

c.

rated dc voltage shall be applied for not less than 3 seconds ±2 seconds between the terminals of the

capacitors.

4.6.4 Insulation resistance (see 3.7). Capacitors shall be tested in accordance with method 302 of MIL-STD-202.

The following details shall apply;

a.

Test condition: Rated voltage, but not to exceed 500 volts.

b.

Special conditions: If failure occurs at a relative humidity above 60 percent, the insulation resistance may be

measured again at a relative humidity of 50 percent ±5 percent.

c.

Point of measurement: Terminal to terminal.

d.

Electrification time: Shall not exceed 1 minute.

4.6.5 Capacitance (see 3.8). Capacitors shall be tested in accordance with method 305 of MIL-STD-202. The

following details shall apply.

a.

Test frequency: 1 MHz ±100 kHz.

b.

Limit of accuracy: ±2 percent or 0.5 pF, whichever is greater.

4.6.6 Dissipation factor (see 3.9). The dissipation factor of capacitors shall be measured at both maximum and

minimum capacitance setting at a frequency of 1 MHz ±100 kHz. The accuracy of measurement shall be within ±10

percent of the limit (see 3.9). The voltage applied shall be less than 30 volts peak.

4.6.7 Temperature coefficient and capacitance drift (see 3.10).

4.6.7.1 Temperature coefficient. Capacitance-change measurement at 80 percent to 90 percent of maximum

rated capacitance setting shall be made at the temperature specified in table VI and at a frequency between 0.1 MHz

and 1.2 MHz. Each measurement shall be made after the capacitor has reached thermal stability. (Thermal stability

has been reached when no further change in capacitance is obtained between two successive measurements taken

at 5-minute intervals.)

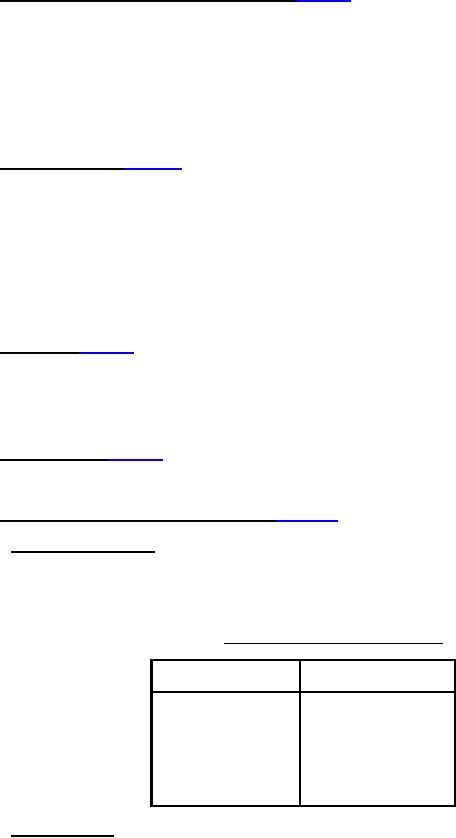

TABLE VI. Capacitance-change measurements.

Sequence

Temperature

25°C ±2°C

Step 1

Start at

-55°C ±2°C

Step 2

Reduce to

25°C ±2°C

Step 3

Return to

Step 4

Raise to

85°C ±2°C

Step 5

Return to

25°C ±2°C

4.6.7.2 Capacitance drift. Calculation of capacitance drift shall be based on the maximum deviation between any

two of the three measurements of capacitance at 25°C (see table VI).

11

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business