MIL-PRF-87217A

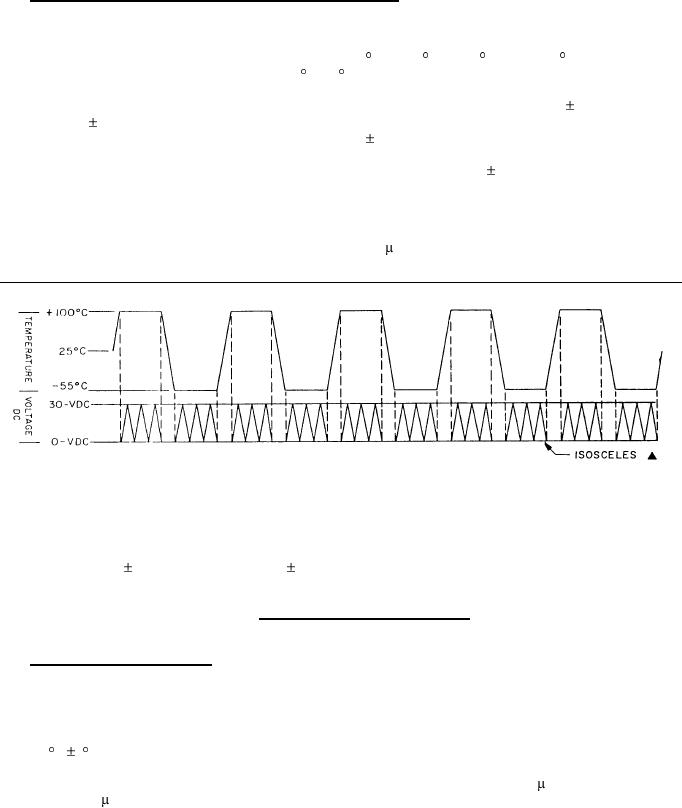

4.7.4 High impedance temperature and voltage ramp (see figure 1).

a. Each part shall be connected with 1-10 megohms in series.

b. Parts shall be temperature ramped for 5 cycles from 25 C to 100 C, to -55 C, and to 25 C with an equally

timed stay at the temperature extremes (100 C/-55 C).

c. Parts shall be voltage ramped during the temperature extremes only. A 0 volt to 30 volt ( 10%) ramp in 30

minutes ( 3 minutes) shall be applied to the RC circuit. After the capacitor reaches 30 volts charge, the

capacitors will be linearly discharged within 30 minutes 3 minutes. When the voltage reaches 200

millivolts, the voltage ramp to 30 volts is repeated (3 ramps during each exposure at the temperature

extremes). For capacitance values above 10 microfarads, use a 60 minute 6 minute ramp to 30 volts.

d. Parts shall be monitored for high leakage current continuously, or scanned at a minimum of once every 0.5

seconds, during the 5 temperature cycles. Noise shall be limited to 6 mV, peak.

e. A permanent record of current excursions in excess of .05 A shall be maintained.

STABILIZE CAPACITORS AT TEMPERATURE EXTREMES AND VOLTAGE RAMP 3 TIMES

(0 TO 30 V dc) 10% AND (30 TO 0 V dc) 10% WHILE MONITORING FOR LEAKAGE CURRENT

FIGURE 1. Voltage and temperature ramp test.

4.7.5 Insulation resistance (see 3.9). Capacitors shall be tested in accordance with method 302 of MIL-STD-202.

The following details shall apply:

a. Test potential: Rated voltage, unless otherwise specified (see 3.1).

b. Points of measurement: Between terminals at the applicable specified temperatures (see 3.1), and at

25 C 3 C.

c. Charge time 5 minutes maximum; however, for capacitance values greater than 1.0 F, an additional 1

minute per F is permitted.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business